Over time, OE fuel pumps will inevitably wear out. A failing fuel pump delivers less fuel to a vehicle’s engine, the prolonged effects of fuel pump failure can develop into a significant vehicle setback. The three key signs of fuel pump failure include:

- Hesitation during acceleration

- Rough idle

- A vehicle that will not start

Hesitation During Acceleration

During acceleration, a vehicle’s engine requires additional gasoline. If a vehicle seems to be accelerating at a slower rate than normal, or if the engine shuts down completely during acceleration, the fuel pump may be struggling to keep up with the engine’s increased need for gasoline.

Rough Idle

If you notice that a vehicle’s idling seems rougher than usual, a clogged fuel pump may be to blame. Debris may be congesting the pump, therefore preventing the proper amount of gasoline from flowing into the engine.

A Vehicle Not Starting

While many factors may impact whether or not a vehicle starts, a faulty or clogged up fuel pump may be the explanation. Take this into consideration when troubleshooting a vehicle that refuses to start.

Replacing a Fuel Pump

Cleaning a fuel tank is an important step in replacing the fuel pump. A dirty fuel tank can lead to fuel pump failures. It is critical that contaminants and loose debris, including rust and sediment, are removed prior to fuel pump installation. Skipping this step can lead to; a clogged fuel strainer, jammed turbine pump, reduced fuel flow and immediate fuel pump failure after replacement.

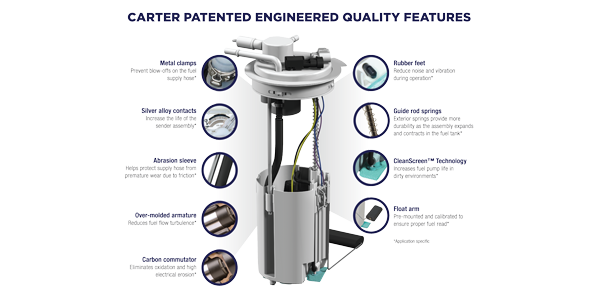

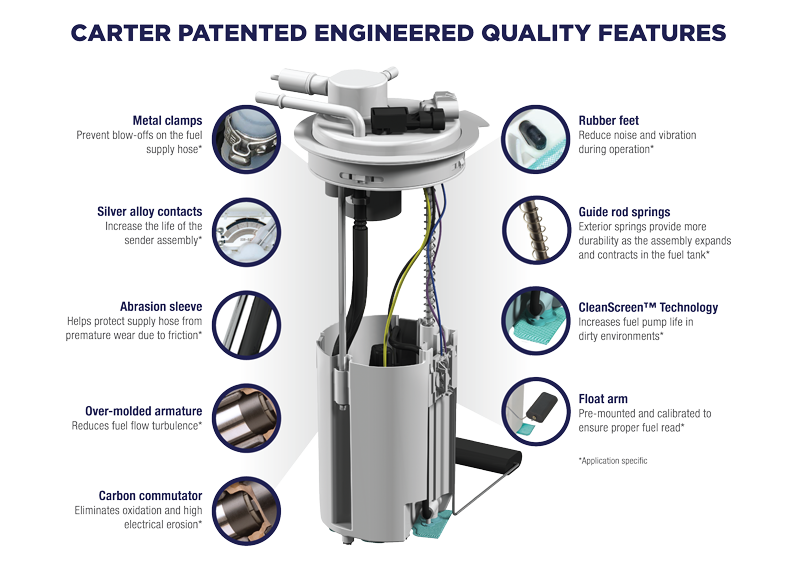

Once the OE fuel pump fails, it is important to choose a high-quality replacement pump. From patented design to higher quality materials, Carter engineering sets the standard for fuel pump solutions that meet or exceed OE fit, form and function with best-in-class coverage. The patented module and hanger assembly contain industry exclusive features all designed to provide longer service life and better performance. Available in mechanical, electrical, assemblies and GDI pumps; Carter® fuel pumps are obvious choice for optimized high efficiency and performance. To learn more about fuel pumps, visit www.CarterEngineered.com.

This article was sponsored by Carter.