When lifting a vehicle, modifications are made to the suspension so that bigger tires can be installed and to provide more clearance under the vehicle for off-road driving. This means the frame and body will be moved up and away from the wheels, which causes the CV axle angles to become extreme, often causing binding, premature wear, and vibrations. On lifted trucks with less expensive leveling kits the cv joint angle can become extreme since the differential is not lowered to correct the axle angle.

A Constant Velocity, or CV, axle is essentially a shaft running from the front differential to the wheel with a CV joint at each end. With an independent front suspension, or IFS, the differential is stationary while the wheels are independently sprung. The front wheels not only have the job of turning the vehicle, but also moving up and down with the suspension. This means the CV axle needs to be able to rotate with the wheel, in addition to the vertical travel of the wheel end of the suspension.

The axles on a truck do a lot of work. They are the final link on your drivetrain that gets your engine’s power to the ground, and they take a lot of abuse. From overheating, to binding, to massive torque loads, the issues facing your axles are made even worse when you add the extreme angles inherent with a lift kit.

The best way to prevent premature axle failure due to lift kit stress is by upgrading TrakMotive Xtended Travel® CV Axles.

THE PROBLEM: A lifted vehicle dramatically increases the stresses of stock components and often exceeds the original design limitations.

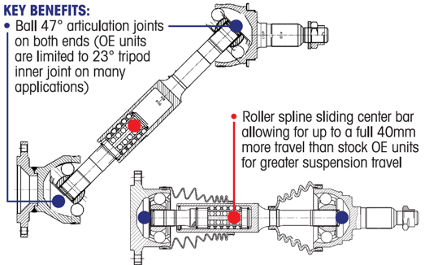

THE SOLUTION: TrakMotive Xtended Travel® CV Axles are designed with a sliding center bar that provides up to 40mm more travel than an OEM CV shaft. Additionally, the CV joints can achieve a up to a 47°articulation angle compared to a maximum 23°articulation angle on a typical OE CV joint.

Additional Benefits Include:

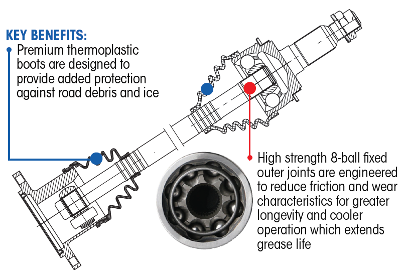

· High strength 8-ball fixed CV inner and outer joints (where applicable) that have 60% more operating angle on the inboard joint, eliminating joint failure from lift kits increased rife height.

· Thermoplastic boots for added protection against rocks, and punctures when off-road, and high strength stainless steel clamps and increased corrosion resistance.

So, if you’re looking for a long-lasting dependable performance in even the Most extreme conditions, we have a solution.

Check out our Tech Minute Video on Xtended Travel® CV Axles:

For more detailed information, explore the benefits of our entire CV Axle offering www.trakmotive.com.