In the market today, an array of powertrains exist—battery electric (BEVs), plug-in hybrid (PHEV), hydrogen fuel cell (FCEVs). Sure, electric vehicles have always been around, but today’s mobility environment is a far cry from that of just two decades ago. One company that is innovating both on the aftermarket and EV side when it comes to equipping the vehicles of today and tomorrow is MAHLE.

The German auto parts supplier, best known for its engine components, is amping up its technology in thermal management as it works with its OE partners on solutions for EVs and other powertrains in the market today. For MAHLE, that also translates to providing the aftermarket with components and tools repair shops need to service these vehicles.

Arnd Franz, CEO of the MAHLE Group, sat down with us to discuss MAHLE’s strategy toward the EV and ICE-vehicle markets and how thermal management systems will be the most vital component of a vehicle for years to come.

AMN: Thermal management and electrification are a big focus for MAHLE. However, EVs make up such a small percentage of the car parc today. Tell us why MAHLE has gone in the direction of thermal management.

Arnd Franz, CEO, MAHLE Group: I think this is a crucial question for MAHLE, but also a crucial question for the whole automotive industry, both OEMs and suppliers. MAHLE has a hundred-year plus history with internal combustion engines and is a leading OE and aftermarket partner for climate neutral mobility At the same time, the whole automotive industry is undergoing a pretty strong transformation, which varies by region. We needed to really figure out what the value is that we can provide our customers on the OEM and aftermarket side, which is an evenly important question for us.

So, we came up with our new strategy MAHLE 2030+. With its mission “Efficiency in Motion,” it really does incorporate all the important enablers for future mobility. In our view, it is not only one solution; it’s a plurality of solutions, that includes electrified vehicles, hybrids and highly efficient and clean internal combustion. Thermal management will be key for all the existing power trains, but especially key to electrified power trains in the future.

AMN: You spoke about providing value to the OE and aftermarket sides. In what way is MAHLE balancing its R&D and innovations in terms of ICE vehicles versus EV and hybrid?

Franz: The internal combustion engine is a very, very mature product. It has undergone certain improvements over the past decades in terms of efficiency and especially emissions. However, electrified vehicles are not new because they have been around since the invention of the automobile. Of course, with our need to decarbonize the transportation and mobility sector and the regulations coming along with that, there’s a lot of activity now around developing electrified powertrains, that will affect aftermarket in the long run. So, if I look at the amount of our R&D that is focused now on electrified powertrains versus ICE, I would say it’s the vast majority.

If you look at our patents, more than 70% of our patents in 2022 were geared toward electrification. This shows the shift on the R&D side towards electrification. That does not mean that there will not be any new ICE engines. We’re following the current trends in the automotive industry.

AMN: With the focus on thermal management, how will this be translated to the aftermarket side?

Franz: In the past, engine cooling and air conditioning have been very important parts of our portfolio. They will become increasingly important with the role that thermal management plays—not only for internal cabin comfort for air conditioning but also for motor cooling. The cooling of power electronics like inverters and onboard chargers, and especially the cooling of the battery, will be the most valuable part of electric vehicles and the vehicle of the future. The question of how the battery will perform over its lifetime and how the battery will continue to be a valuable part to retain its value for the whole vehicle will be crucial. Therefore, we see that most of the aftermarket business of the future will be around the battery of the vehicle when we speak about the powertrain.

There are a couple of things that are important for battery lifetime and efficiency. One is the battery management system; another one is the thermal system; and the third one is cell performance and cell defects. We believe there is going to be a big aftermarket business all around the traction battery, all around the lithium battery. This is something that MAHLE is focusing on w ith the first products we’ve introduced as part of our BatteryPRO workshop equipment suite.

With this, we are monitoring battery health over its lifetime through on-board diagnostics (OBD II) information and testing its charging and discharging behavior. And therefore, addressing an important pain point for used cars, which is the residual value when it comes to trading vehicles, but also when it comes to identifying battery deterioration early on and taking the right measures to make sure the battery performs well over its lifetime.

AMN: Can you explain the BatteryPRO suite?

Franz: The BatteryPRO suite consists of several products for the service of battery driven vehicles. Our latest innovation is E-HEALTH Charge. It’s more than an app. It’s hardware, so you can plug it into the OBD II port as well as also plug it into the charging port of the vehicle. Then, it tests the capability and the state of the battery by base charging it. This is a piece of equipment that could be used by garages, by car dealerships and other operators in the aftermarket. It will become part of our overall workshop equipment for players in the aftermarket.

AMN: Is this a global product?

Franz: It is, but, of course, it’s more relevant to the markets that have a population of battery electric vehicles, such as Europe, where regulations are geared toward battery electrical vehicles when it comes to decarbonization.

The US market, in our expectation, will develop more to a plurality of solutions for decarbonization. So, we expect that by 2035, around 60% of new registrations in North America will be battery electric vehicles, and around 40% will be with an internal combustion engine still. So, it’s still a big shift, but it’s quite different from Europe where we expect that by 2035, 95% of all new vehicle registrations will be battery electric vehicles only.

AMN: With this shift, how will MAHLE balance supporting the OE side of the business versus the aftermarket? How will the company continue to innovate when it comes to ICE vehicle components?

Franz: We’ve been very clear to our stakeholders and especially to our customers that we will continue to support internal combustion engine components wherever we are currently a leading offering in the market. This is for pistons, for piston rings, for valve train components and many more components. We will continue to serve our customers as long as there is demand. And we believe there is no real way for successful decarbonization without an internal combustion engine solution that is run with sustainable fuels.

Then on the aftermarket side, people always underestimate the number of years that vehicles stay on the road. So, the average age of vehicles in the United States now on the light vehicle side is around 12 years. That number goes up every year because vehicles last longer and are better built. We will continue that responsibility in supporting the aftermarket and grow that business. The aftermarket business for MAHLE is of immense importance. It’s part of our overall strategy going forward. It’s part of our overall strategy for the next decade. So, that’s for electrification, thermal and internal combustion engine components.

AMN: With thermal management, what is MAHLE seeing as challenges that exist today in the market in meeting OE requirements?

Franz: We believe in a factor of three. So future electrical vehicles will have three times more thermal components and value of thermal components installed in the vehicle. That’s why it will not only become more important for the OE business, it will also become more important for the independent aftermarket operators when it comes to servicing and repairing those vehicles.

We will have a much stronger focus on designing the thermal system in a way that it takes care of all those things: the battery, power electronics, cabin and motors plus the vehicle’s charging infrastructure. We will have more demanding specifications for the components. For example, for the battery cooling plate, which depending on the design, can be a component that’s up to 20 square feet in size. This is true for the electrical compressor, and we were one of the first to introduce 800-volt electrical compressors.

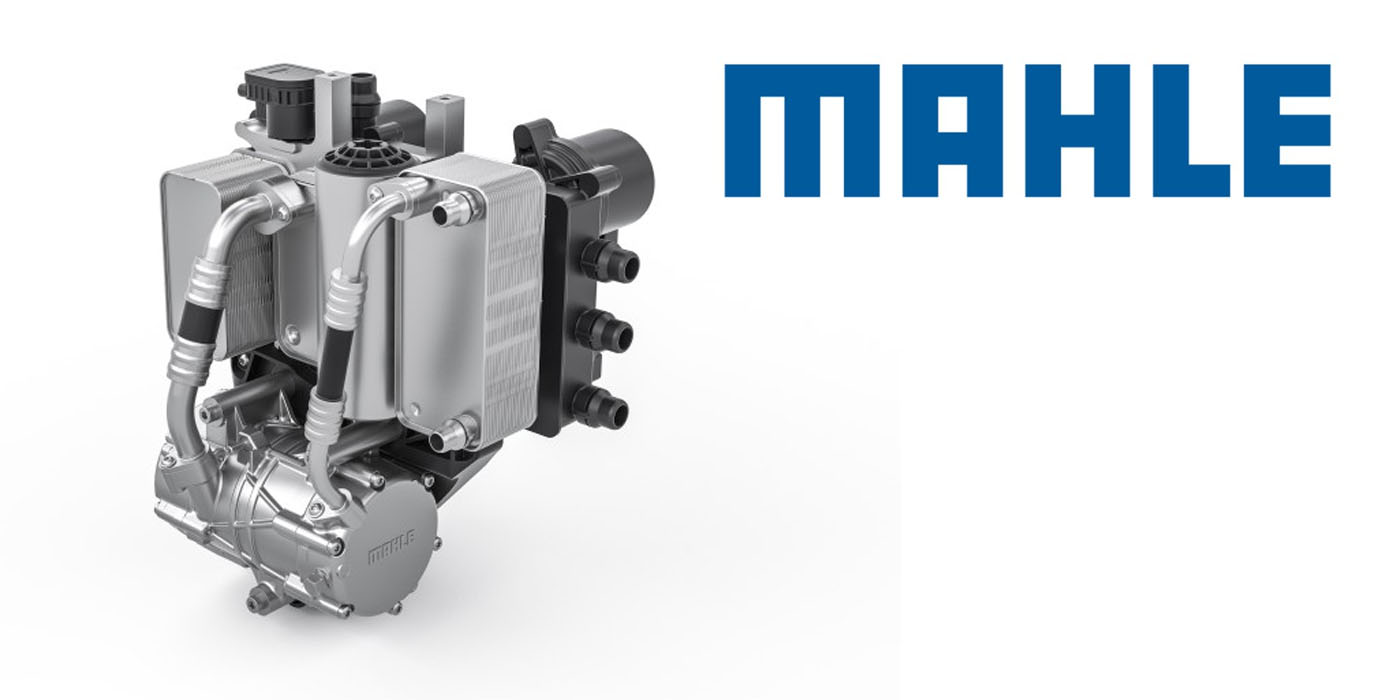

We’ve just introduced our new thermal management module, which combines chillers, heat exchangers and valves, so the vehicle can control and steer the flow of coolant and refrigerant. This is just an example of the sophisticated components compared to just regular thermostats or coolant thermostats that are installed in vehicles today.

With thermal management getting more sophisticated and complex, players in the aftermarket need a partner that can provide those parts in the future, but also provide the intelligence, the know-how and the training for those applications. We believe that MAHLE is a great partner for this because we have strength both on the OE side and the aftermarket.

AMN: We discussed the BatteryPRO Suite, but what other resources is MAHLE offering aftermarket professionals to get up to speed on these thermal management technologies?

Franz: It will take some time until electrical vehicles really hit the independent aftermarket because many of them are under eight-year warranties for the battery and for other things. But I believe it’s important that independent aftermarket operators inform themselves and train themselves in battery electrical vehicles early. We continue to add battery electrical vehicle content to our training platforms, “MAHLE eLearning”, whether it’s virtual or in our physical trainings or independent aftermarket events and conferences. With our trainings on our complete product portfolio, from engine parts and filters to thermal management, e-mobility and workshop equipment, we are a strong and reliable partner for independent workshops and support them in gearing up for the future.

I think this is a core responsibility for us as an OE parts and system supplier to transfer the latest knowledge to the independent aftermarket. We believe that will be of increasing importance that the data about vehicles in the field will become more transparent so that everyone, the OEMs, the garages, the suppliers and other players in the aftermarket can learn together how to make sure that vehicles on the road stay safe and efficient, and be run and operated at an affordable cost. In times of inflation, this is a challenge for many people to really make sure that mobility is something they can afford.

AMN: That ties in with the Right to Repair initiatives that are happening now.

Franz: Absolutely. I think data is key to all the things that I mentioned—safety, efficiency, environmental friendliness, but also affordability of mobility in the future. We believe that since vehicles are becoming more and more software and data-driven, and vehicle technology is more and more complex, many things can be solved and improved by software updates. With technology, there are more opportunities than ever to understand vehicle behavior in real life and on the roads.

We believe that the exchange of data from the independent aftermarket to the OEMs and backwards will be crucial for the future of mobility. And therefore, we strongly support Right to Repair and access to data initiatives worldwide. We also strongly believe that access to service history of vehicles and also access to historical technical data during driving is important to understand how we can improve vehicles and better service and repair them to the advantage and the benefit of the consumer.

AMN: Hydrogen fuel cell technologies are being developed and tested in the market today. What is MAHLE’s outlook for providing components for those types of powertrains?

Franz: We closely monitor what’s going on in other technologies outside battery electrical vehicles. One example is the decades-long experience we’ve had with flex-fuel engines in Brazil that already have decarbonized 50% of the light vehicle sector and fleets in the country. So, biofuels are a part of the equation in our view as well as hydrogen.

With vehicles, there are two basic ways of using hydrogen. One is fuel cell technology and the other one is hydrogen combustion. With fuel cell technology, we’re working with almost every fuel cell manufacturer for mobile applications worldwide—not only in the US or in North America but also in Europe, China and Japan.

We’re quite excited about this. At the moment, it looks like the applications for fuel cell will be more on the heavy-duty side and more in the longer-range side. We believe there is still some work to do on stronger and higher power fuel cells as well as making fuel cell applications that meet the durability requirements for heavy duty operators. Towards the second half of the decade, we believe there will be more penetration from fuel cell technology into trucks and into some stationary applications.

When it comes to the hydrogen combustion engine, we are also working with several OEMs on this. We believe that it’s close, but there are some technical questions that need to be answered. Durability is always a topic, especially for the heavy-duty side. We believe that due to the relatively lower number of adaptations needed, moving from diesel to hydrogen on the motor side is a very good prospective for hydrogen combustion engines to become a competitive solution for the trucking industry.

It will be interesting to follow the competition between these technologies (electric batteries, fuel cell and hydrogen combustion) in operating cost, durability and serviceability. As MAHLE, we are developing partners for all those technologies.

AMN: What more would you like the aftermarket to know about MAHLE right now?

Franz: I think it’s important to say that No. 1, the aftermarket business and supporting our customers in garages, fleets and other service areas is key and strategic for MAHLE. Our intention would be to double our aftermarket business this decade between 2020 and 2030. This is across the board and includes our North American business. We believe that the concise portfolio of products we have is one key. The other key will be service to our customers in the form of training and equipment and eventually data and software that will become a key part of successful aftermarket operations to keep vehicles on the road safe and affordable.