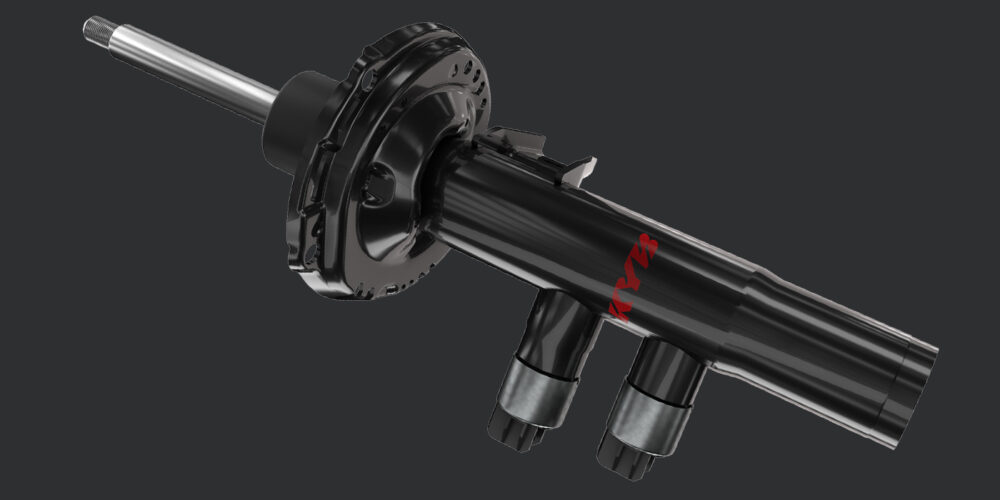

KYB Corporation announced its electronically controlled shock absorbers have been adopted by Volkswagen Group to equip new Tiguan, Passat Variant, SKODA Superb and Kodiaq models with the new DCC Pro (Dynamics Chassis Control Pro). The market introduction is scheduled during the first quarter of 2024, the company said.

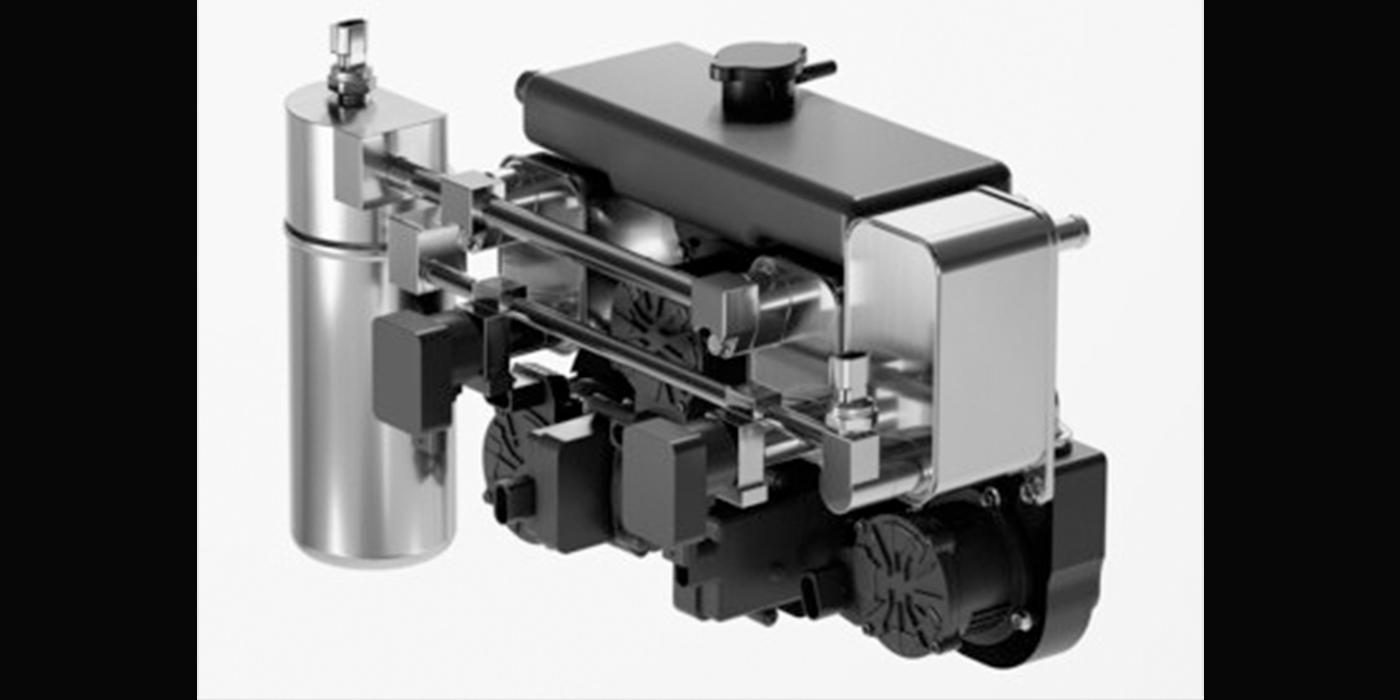

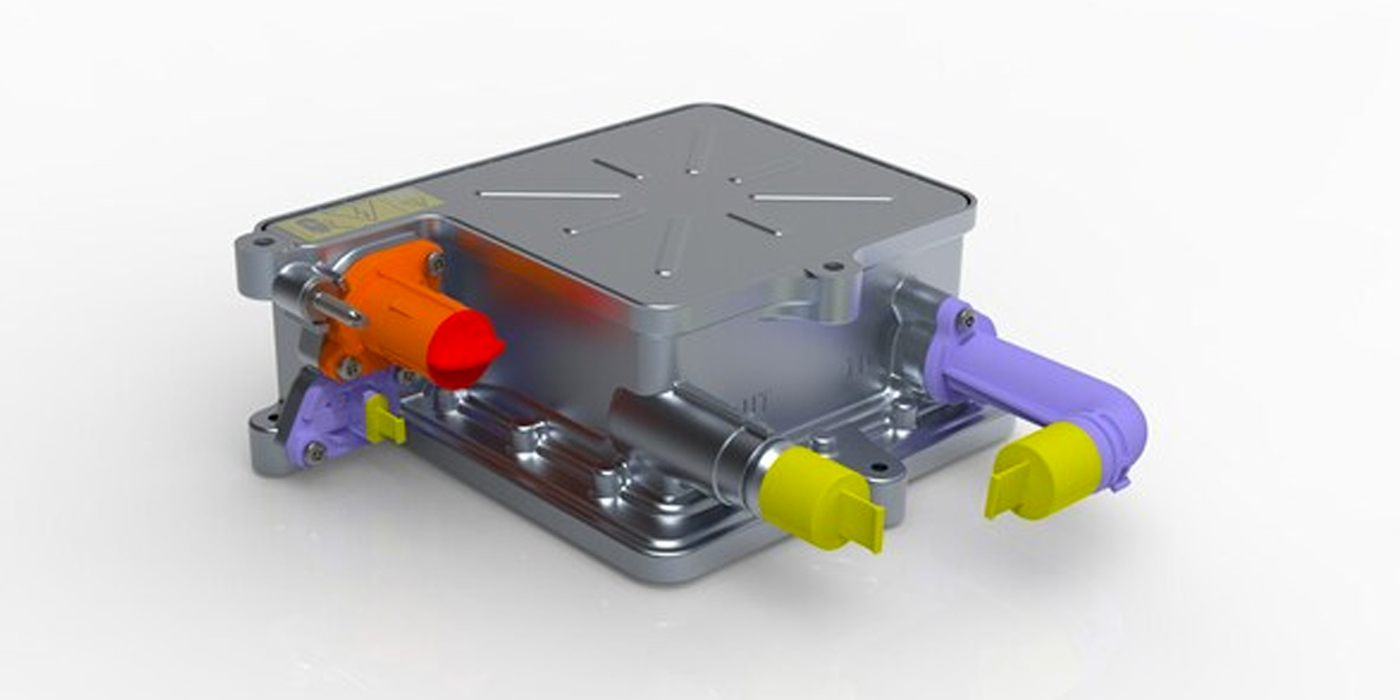

DCC Pro systems use double-valve shock absorbers to independently control the extension and compression oscillations caused by the car body and the wheel movements while driving, according to KYB.

These valves react to road conditions and driving situations in a few milliseconds. According to KYB, “The ECU activates the respective extension and compression solenoids to adjust independently the internal pressure of the shock absorber to suit road conditions and the driver’s preference (from comfortable to very sporty). The damping characteristics are automatically adjusted in a continuous way, which, in conjunction with the full independence between extension and compression movements, brings the vehicle comfort and control to the highest level. This provides safe, dynamic manoeuvrability and an unprecedented ‘flying carpet’ ride experience.”

KYB and the VW Group have been working together for several years, including the sporty Audi RS suspension, and since then have co-operated extensively for the VW brand, the companies said. This new development is part of KYB’s policy to further strengthen its partnership with the German car manufacturer.