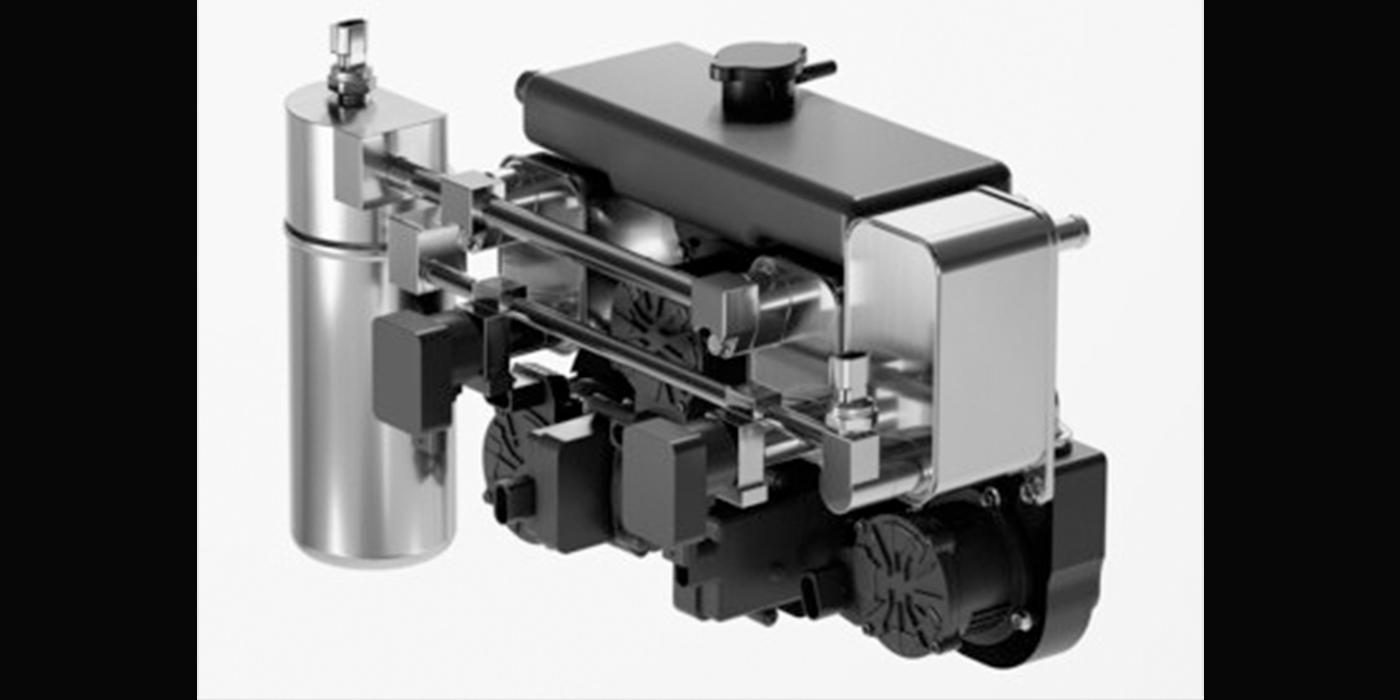

With its Veyron and Chiron super sports cars, Bugatti developers have succeeded in designing a brake caliper that can be produced by 3-D printing. While the main material used for the additive production of vehicle components to date has been aluminium, the new brake caliper is made from titanium. The company says this is the world’s largest functional component produced from titanium using a 3-D printing processes.

With its Veyron and Chiron super sports cars, Bugatti developers have succeeded in designing a brake caliper that can be produced by 3-D printing. While the main material used for the additive production of vehicle components to date has been aluminium, the new brake caliper is made from titanium. The company says this is the world’s largest functional component produced from titanium using a 3-D printing processes.

This new milestone in the development of 3-D printing was reached in cooperation with Laser Zentrum Nord of Hamburg, part of the Fraunhofer research organization since the beginning of the year. Vehicle trials for the use of the 3-D titanium brake caliper in series production are expected to start in the first half of the year.

“Vehicle development is a never-ending process. This is particularly true at Bugatti,” said Frank Götzke, head of new technologies in the Technical Development Department of Bugatti Automobiles S.A.S. “In our continuing development efforts, we are always considering how new materials and processes can be used to make our current model even better and how future vehicles of our brand could be designed.

“As our performance data are often at the physical limits, we are especially demanding,” added Götzke. “This is why Bugatti always goes at least one step further than other manufacturers in the development of technical solutions.”

Götzke has worked for the Volkswagen group for more than 22 years. He joined Bugatti in 2001 and played a key role in the development of the Veyron as head of chassis development and in the development of the Chiron1 in his current position.

Bugatti says it currently uses some of the most powerful brakes in the world on the new Chiron. The brake calipers, it adds, were an entirely new development. They are forged from a block of high-strength aluminium alloy. With eight titanium pistons on each of the front calipers and six on each of the rear units, these also are the largest brake calipers currently installed on a production vehicle. The brake calipers of the Chiron are produced using bionic principles on the basis of a natural model. The new architecture combines minimum weight with maximum stiffness. The inspiration for the design and mode of operation of the brakes was taken from motorsports.

With the newly developed titanium brake caliper from the 3-D printer, Bugatti is now going one step further and breaking new ground. This particular titanium alloy, with the scientific designation of Ti6AI4V, is mainly used in the aerospace industry. The material offers considerably higher performance than aluminium. The new titanium brake caliper, which is 41 cm long, 21 cm wide and 13.6 cm high, weighs only 2.9 kg. In comparison with the aluminium component currently used, which weighs 4.9 kg, Bugatti could therefore reduce the weight of the brake caliper by about 40 percent at the same time as ensuring even higher strength by using the new part.

The first trials for use in production vehicles are due to be held in the first half of the year; the time schedule is still to be finalized. At that stage, the engineer promises that it will be possible to considerably shorten production times, especially for machining.

To learn more about this new technology, stay tuned for this week’s AMN Video.