The Chinese automotive supplier Protech has received the “Crash Test Facility of the Year” award for its facility in Nanjing, China. The facility was developed and constructed by MESSRING, a company out of Krailling, Germany. This is the fourth time that MESSRING has received this award for a facility it has constructed.

English publishing company UKIP has presented the award since 2006 to honor outstanding projects and innovations in the automotive industry. John Thornton, chairman of the Automotive Testing Technology International Awards, explained on behalf of the international expert jury just why they selected the facility from Protech this year: “Protech is a deserving winner of the ‘Crash Test Facility of the Year’ award. There was stiff competition in this category with several state-of-the-art passive safety centers in the running, but Protech’s Nanjing facility won thanks to its new advanced technologies and cutting-edge dummy calibration laboratory, which – thanks to the key role played by leading manufacturer MESSRING – is among the highest specification commercially available in the Asian automotive sector.”

In receiving this award, MESSRING continues to build on its success in previous years and once again positions itself as a trendsetting partner. “As a manufacturer of crash test facilities, this award is both a major honor and an acknowledgment of our work,” said Dierk Arp, general manager of MESSRING. “And that is particularly true in this case because this project was the first time we planned and constructed a complete dummy calibration lab equipped with state-of-the-art technology for a client. At Protech, we were truly able to offer everything from one source, in line with our slogan ‘designed to be compatible.’”

At the end of 2012, Protech decided to construct a complete crash-test facility with MESSRING, as well as a laboratory for automated dummy calibration at the new location in eastern China. In this context, the goal was for the calibration laboratory to set new benchmarks in the certification of dummy sensors. In addition, the fact that all of the measurement instruments, test stands (including the crash-test facility) and calibration systems are connected is one-a-kind, says the company. Together, they are all managed using the centralized, company-wide software package CrashSoft, which not only plays a key role in ensuring data security and quality, but is also unique throughout China, according to Protech.

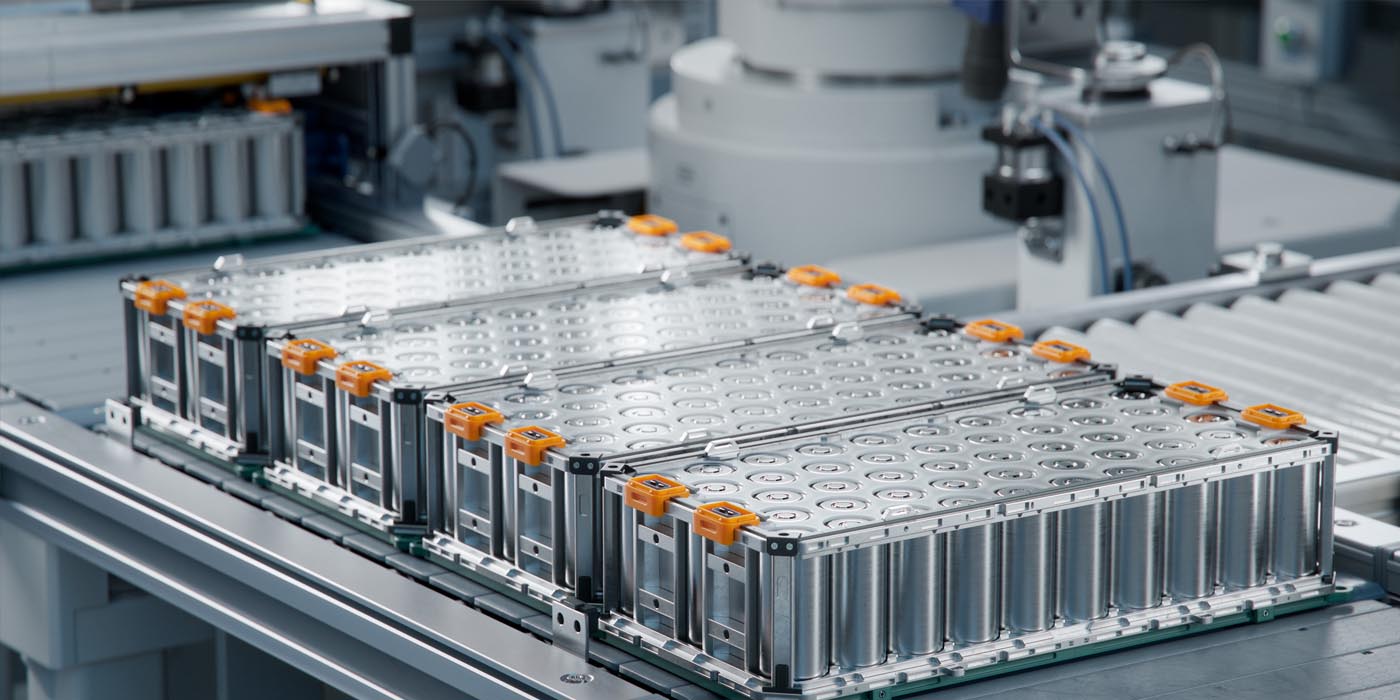

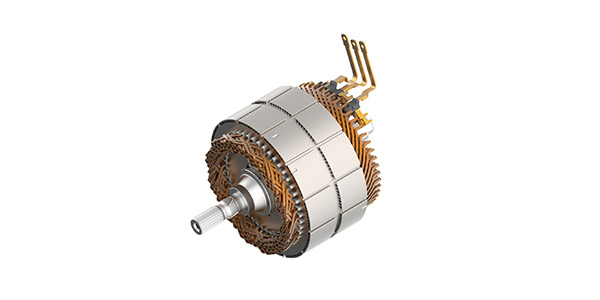

Including the preparation rooms and laboratory, the crash-test facility measures 7,900-square-meters (85,034.89-square-feet). The MicroTrack system installed by MESSRING measures 136 meters (446.19 feet) in length and makes top speeds of up to 90 km/h (55.9 mph) in crash tests possible. The tried-and-tested electric motor, which accelerates test vehicles along the track system, two film pits for video and photo documentation, a flying floor for side-impact tests and a variety of special barriers are just some of the test components installed. Protech not only uses the facility for testing its own products, such as airbags and electronic parts, but also makes it available to other vehicle manufacturers and suppliers.