CLEVELAND — Ford Motor Co. today marks the start of production of its advanced fuel-efficient EcoBoost engines at Cleveland Engine Plant No. 1.

Ford invested $55 million to retool and reopen the plant, which had been idled in 2007. About 250 employees are returning to the plant to build the new engines.

Cleveland Engine Plant No. 1 initially opened in 1951 as Ford’s first engine plant in Ohio. Since then it has produced more than 35 million engines, including 24.3 million engines in the famous 302 and 5.0-liter V-8 family. In 2004, Ford invested $350 million into the plant for redesign and installation of an all-new assembly line as well as block, crankshaft and cylinder head machining lines.

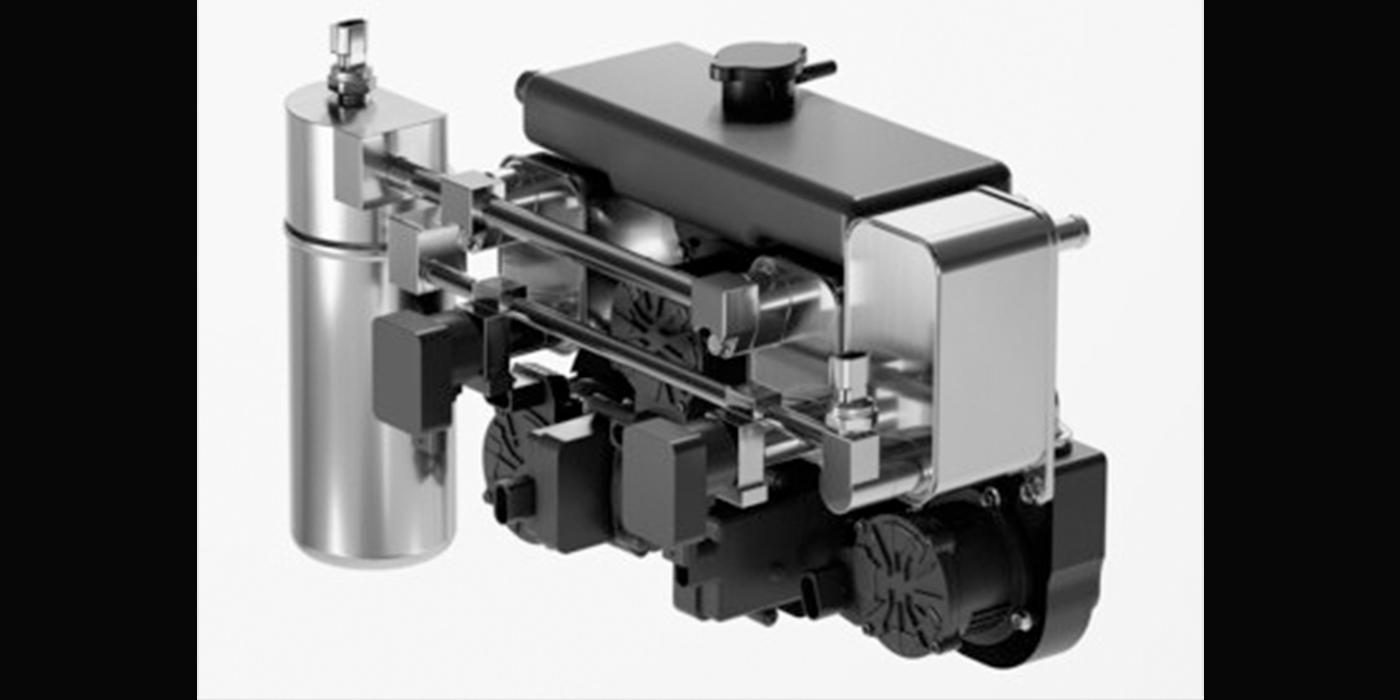

Cleveland Engine Plant No. 1 has been outfitted with a flexible powertrain manufacturing system that can be easily reprogrammed to perform new tasks with minimal disruption to production. Plant upgrades also included a special turbocharger installation and test line. After the turbos are added, each EcoBoost engine is turned on speeds between 60-600 RPM using an electric motor to simulate running conditions. Unique to the Cleveland site, this "cold test" checks for proper buildup of pressure on the turbo output side before the engine ever leaves the factory.

To ensure quality is built into the engine from the outset, Ford developed a new, internal database for its operations. Each engine will be built with a sophisticated, embedded engine "birth history" that allows plant engineers to track every stage of production.

The engine history, maintained in a microchip database, includes hundreds of metrics and allows engineers to trace the precise path taken by any part so any quality control issue can be traced back to its source.

The 3.5-liter EcoBoost V-6 engine, the first V-6 direct-injection twin-turbocharged engine produced in North America, will make its debut in the 2010 Lincoln MKS, Lincoln MKT, Ford Taurus SHO and Ford Flex this summer. A V-6 EcoBoost engine will be available for the F-150 in 2010.

EcoBoost technology combines turbocharging and direct gasoline injection to deliver up to 20 percent improved fuel economy, 15 percent fewer CO2 emissions and superior driving performance compared with larger displacement engines. The "downsize and boost" strategy provides consumers better fuel economy without sacrificing the power they want for driving performance.

"This launch of the first EcoBoost engine is a significant milestone in Ford’s overall commitment to deliver affordable fuel efficiency for millions," said Barb Samardzich, vice president, Global Powertrain Engineering. "We’ve spent the past two years developing EcoBoost technology and now our customers will finally have the opportunity to experience what this engine delivers, the power of a V-8 with the fuel economy of a V-6."

Ford will deliver EcoBoost across the full range of its product portfolio, from small cars to large trucks and by 2013, will offer EcoBoost engines, V-6s and I-4s, on 90 percent of its North American nameplates. Within three years, Ford expects to deliver 750,000 EcoBoost-equipped vehicles per year in North America and 1.3 million vehicles globally.