NASHVILLE, Tenn. – TMD Friction has announced the launch of a new friction material for heavy-duty applications using air disc brakes. The new material is designated Textar T3080 and is engineered for applications where high torque levels are required to meet the FMVSS121 Stopping Distance Regulations. In addition, TMD says Textar T3080 already meets the 2014 and 2021 “Better Brakes Rules” environmental regulations for heavy metals and copper content, an upcoming challenge facing the brake friction industry.

Multiple friction levels are required to best optimize pad and rotor life for different truck, tractor and trailer applications and T3080 rounds out Textar’s North American Air Disc Brake Friction product portfolio by adding a material for the most extreme torque applications on the road, TMD says.

As the North American heavy truck market shifts more to air disc brakes, a key issue is the cost justification of this new brake product. Tom Green, managing director of TMD Friction North America noted, “If disc brakes are to replace drum brakes in large numbers, their acceptance will be based on initial and life cycle costs when compared to drum brakes. Disc brakes cost more upfront, so it is critical to maximize life and minimize operational costs. Textar now has four different friction materials for the North American air disc brake market. Each is designed to optimize the life cycle costs for a particular duty cycle.”

Jim Clark, TMD’s director of engineering for NAFTA, added, “You don’t have to look far to find examples of multiple levels of brake lining friction to optimize brake life. Current drum brake linings on North American commercial vehicles have three distinct friction levels that rate at 20,000 lbs., 23,000 lbs., and the higher GAWRs. While the formulation, quality and consistency of any friction material product has a lot to do with its wear properties, a basic rule of friction science simply states, ‘the lower the friction, the longer the life of the friction material’. This also applies to the rotor. The lower the friction of the disc pad material, the longer the rotor will last. Besides improved life, having multiple friction levels is the best way to address brake balance problems the disc brake faces when mated to drum brakes. We have already seen disc/drum brake compatibility as an issue in working with several large fleets.”

In dynamometer wear tests, two air disc friction materials with different effective coefficients of friction were tested by TMD. Results showed that with a higher effective coefficient of friction (0.38) the pad wears anywhere from 40 percent to 80 percent more than the lower friction pad (0.28).

“Given the large difference in wear rates between the high and low ends of the typical friction range, it is important to select the appropriate friction level in order to maximize pad life, rotor life and maintain safety,” said Clark. “This is why TMD has developed multiple friction materials for North America, Textar – T3050, T3070 and T3080. They cover all the GAWR ratings. We also offer a special material, one of the European market leaders Textar T7400, for the transit bus and refuse truck market.”

HDA Truck Pride Member Southside Trailer Service Expands

The company acquired PBS Brake & Supply in Syracuse, NY.

HDA Truck Pride announced that long-time member Southside Trailer Service acquired another HDA Truck Pride member formerly known as PBS Brake & Supply.

With over 105 collective years of industry experience between the two companies, this acquisition expands the position of Southside Trailer Service along the I-90 corridor from Erie, PA, all the way to Syracuse, NY, "demonstrating Southside’s commitment to serving their customers with excellence," according to HDA Truck Pride.

DMA Announces BULLDOG HD 90-Day Risk-Free Guarantee

This is in addition to the company’s existing warranty.

Hunter to Exhibit New HawkEye XL Aligner at MATS

New commercial alignment system offers speed, versatility and ease of use, Hunter says.

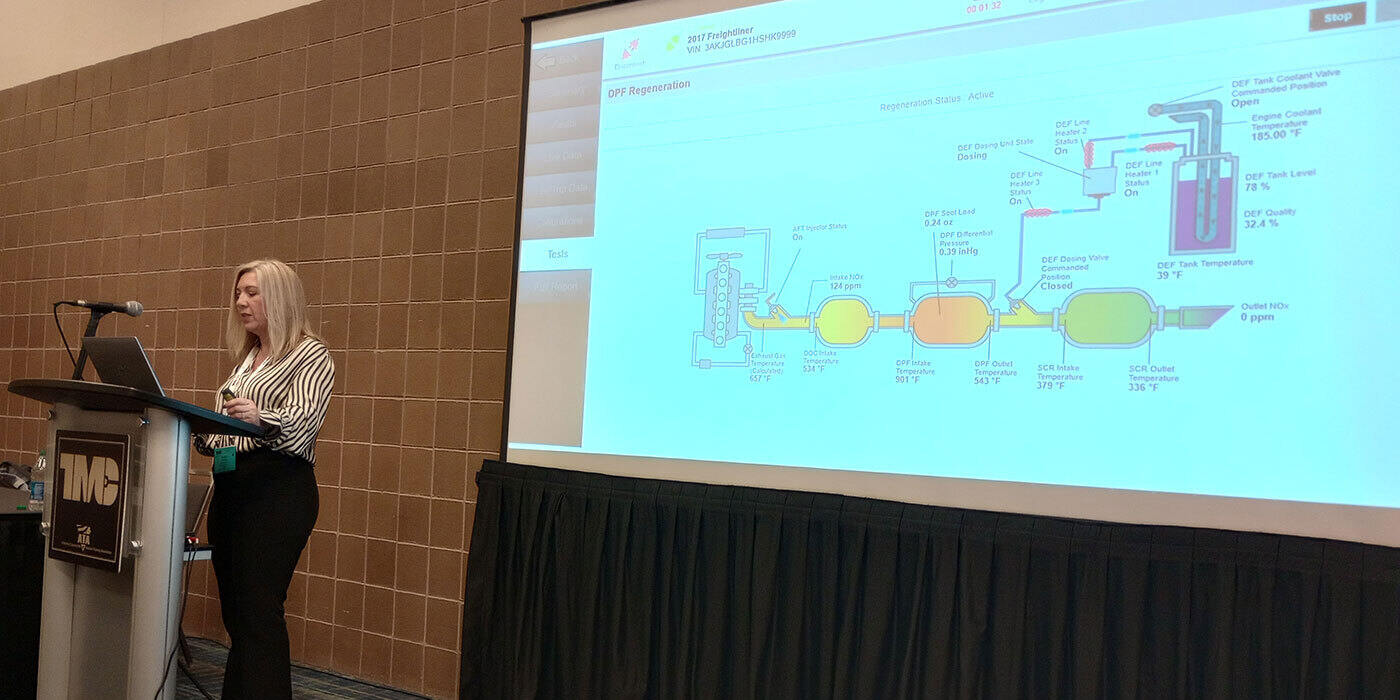

Mitchell 1, NEXIQ Collaborate to Streamline Truck Diagnostics

Technicians can navigate from one information source to the other through the eTechnician diagnostic tool.

Kahgo Truck Parts Joins Power Heavy Duty

While the full-line distributor’s U.S. presence began in 2014, its history in heavy-duty truck parts runs much longer.

Other Posts

Navistar Prepares for Autonomous Commercial Pilot Program

Navistar partnering with Plus to integrate autonomous driving technology into International vehicles.

HD Repair Shops Report Increases in Counter Sales, Labor Rates

The data comes from a Fullbay report published in partnership with ATA’s Technology and Maintenance Council.

HDA Truck Pride Adds Hawaii Truck Parts

Over the past 30 years, the business has evolved into a key player across multiple Hawaiian Islands, venturing into parts sales on Oahu.

Power Heavy Duty Welcomes Childers Auto and Truck Parts

Membership in Power Heavy Duty will help Childers focus on growth and expansion.