TI Fluid Systems, a global supplier of automotive fluid systems technology, announced today that it will provide thermal coolant fluid carrying loops for a large family of Hyundai, Kia and Genesis brand vehicles, starting with the NE EV, a new battery electric compact crossover based on the futuristic “45” concept vehicle.

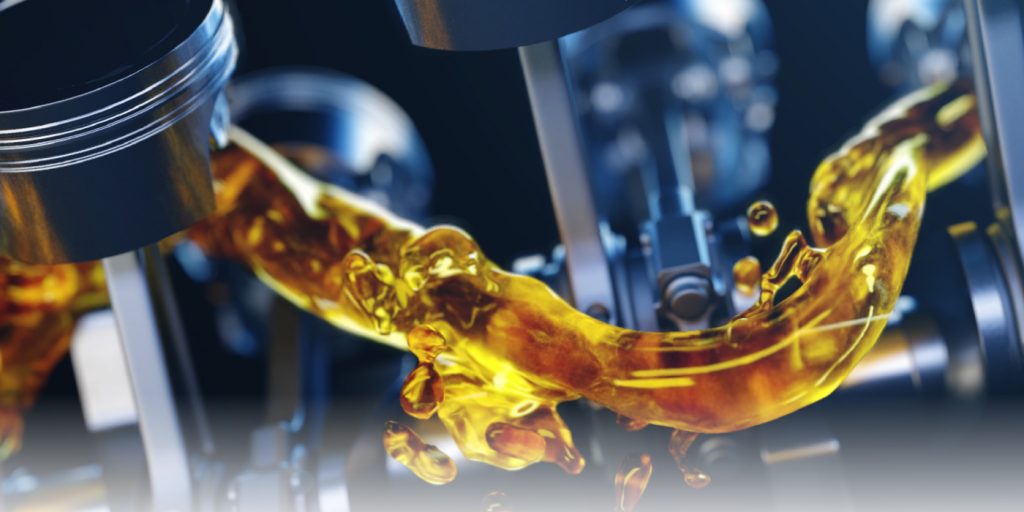

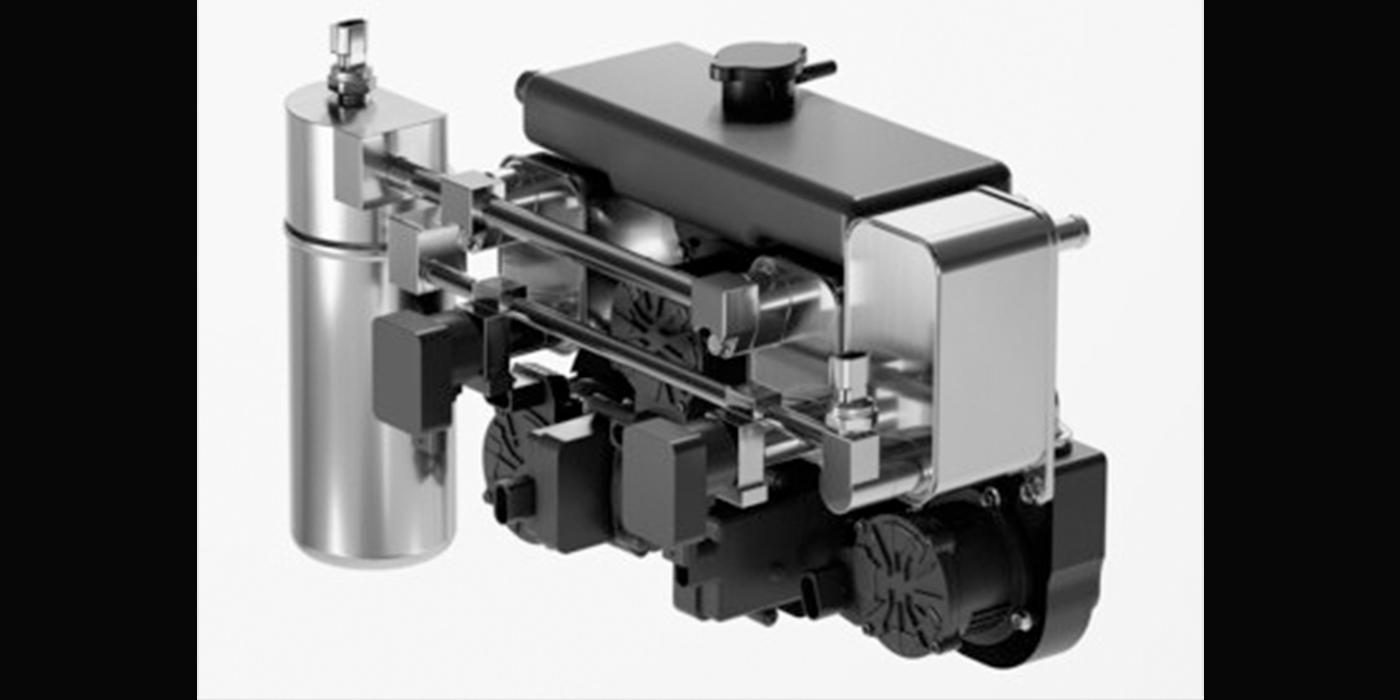

Starting in January, coolant fluid carrying systems will be supplied by TI Fluid Systems across eight different Hyundai battery electric vehicle platforms, all produced in South Korea. The new fluid carrying products apply our innovative approach for light weight and optimized engineered polymer lines produced from nearly 100% nylon material along with quick connectors that are molded, formed and assembled in various diameter sizes for the battery and motor drive thermal management.

“We are proud to contribute our nylon and other expertise and experience in fluid and thermal management systems to this exciting evolution of battery electric vehicles,” said Bill Kozyra, president and CEO of TI Fluid Systems. “We have enjoyed a tremendous partnership with Hyundai for many years and we look forward to supporting these unique global BEV platforms as they expand in the various regional markets.”

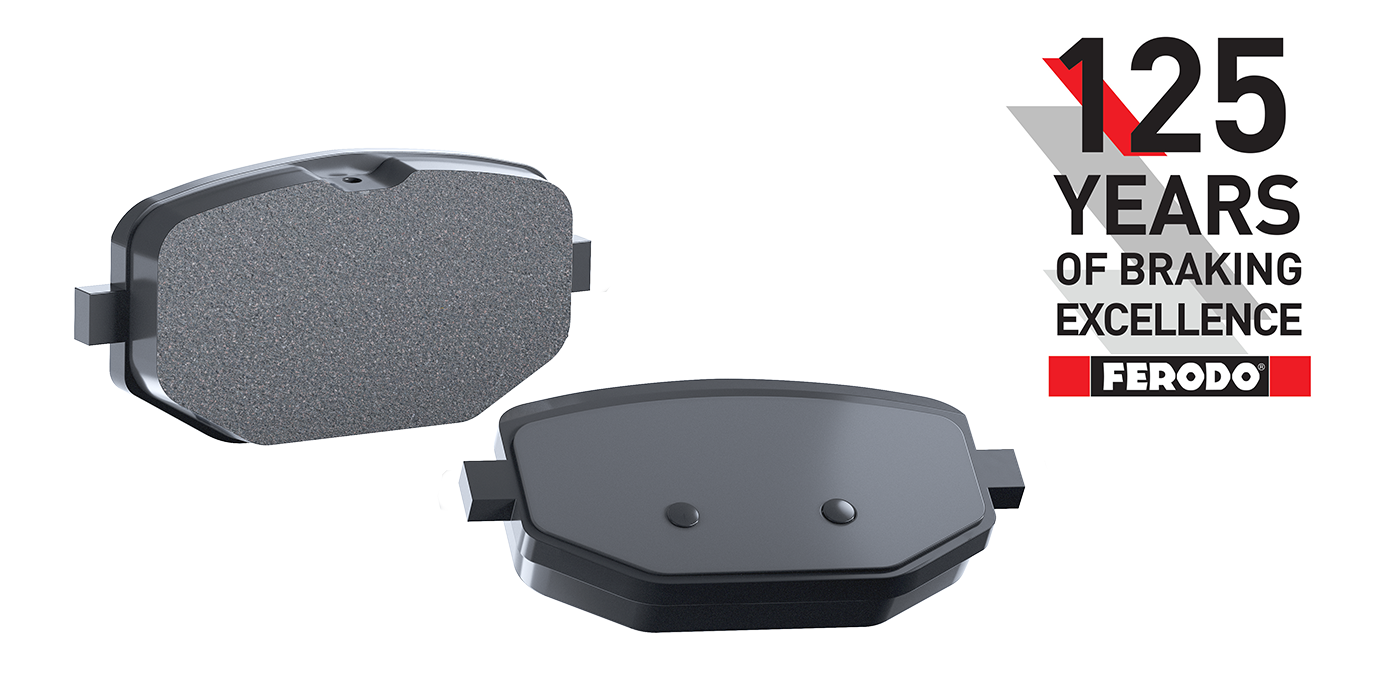

Hyundai plans to expand its BEV lineup to 25 vehicles by 2025, the first of which is launching in January 2021. TI Fluid Systems will be providing the brake line bundles for the new BEV models as well as the fuel tank assemblies and fuel lines for several current Hyundai hybrid EV models.

TI Fluid Systems has been a longtime supplier to Hyundai, providing brake and fuel systems, fuel tank and delivery systems, powertrain systems and thermal management systems to more than 50 different Hyundai vehicle lines worldwide.