NRS Brakes has specifically designed pads for Electric/Hybrid vehicle technology. Advanced driver-assistance systems (ADAS) vehicles demand higher quality of all parts, especially safety items such as brakes. Here are a few of the reasons why:

• As moisture creeps through the porous nature of the friction material it is compromising the untreated backing plate.

• Usually moisture in the friction material is dissipated as heat is created through normal braking routines.

• Hybrid and electric vehicles do not experience this same creation of heat. As a result, we are seeing a significant increase in brake pad separation (failure) that is beginning to become widely recognized as a result of corrosion.

NRS says its galvanized backing plates ensure no rust or corrosion occurs from lack of use due to regen braking. The company’s patented mechanical attachment system physically adheres the friction material to the backing plate. This ensures the pad material cannot separate from the backing plate for the entire life of the brake pad.

As environmental concerns continue to grow – traditional pads still utilized parts and materials that ignore this issue. Here are some of the impacts:

• On our roads, there is debris from more than 2 million brake pads released into the environment each day in North America alone.

• More than 3 million pounds of rust, and paint. All of this material contains toxic amounts of copper, iron, and lead.

• There are enough toxic chemicals and debris from brake pads on North American vehicles to fill 4-million large-sized coffee cups or nearly 70 transport trailer truck loads.

NRS says its brake pads are made from galvanized steel and were designed with the environment in mind.

To find out more about NRS Galvanization, click here.

According to NRS, the company has engineered the first Safety Braking Zone into every one of its brake pads. Instead of adhesives, NRS brake pads have in-situ galvanized hooks called SHARKMetal on the backing-plate surface. These hooks provide mechanical retention of the friction material, overcoming inadequacies of adhesive usage.

Find out more about NRS attachment technology, click here.

The company’s semi-metallic brake pads have more durability and longevity than traditional pads.

Find out more about NRS Premium Friction Materials here.

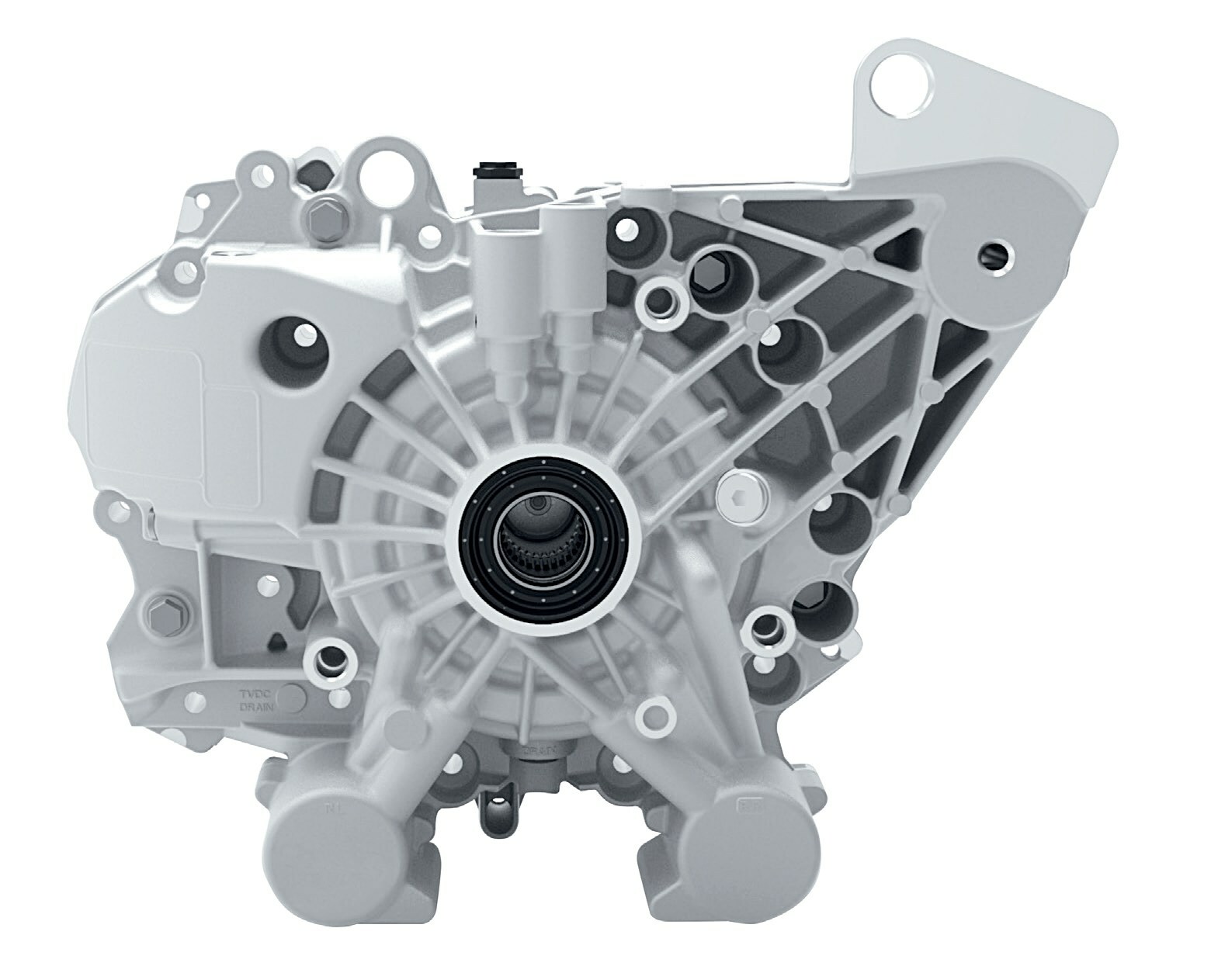

Noise Canceling Piston Insert

This revolutionary noise suppression device snaps into place and works with every open piston caliper with ease. The floating design reduces vibration, which reduces brake noise by 90%, according to NRS.

Tesla Model 3 – Front Brake Kit

Fits: 2017-2020 – non-performance model

Models: Tesla Model 3 – Front brakes

Features and Benefits:

• NuLok tabbed shim technology resulting in no-shim migration

• Galvanized steel backing plates ensuring backing plate will survive the entire life cycle of the friction material

SKU: D2195

$199.99

Click here for more info.

Tesla Model 3 – Rear Brake Kit

Fits: 2017-2020 – non-performance model

Models: Tesla Model 3 – Rear Brakes

Features and Benefits:

• NuLok tabbed shim technology resulting in no-shim migration

• Galvanized steel backing plates ensuring backing plate will survive the entire life cycle of the friction material

SKU: D2283

$199.99

Click here for more info.