MADISON, Ind. – Repair shop owners are facing growing customer demand and, as a result, are looking for ways to improve bay productivity in order to move more vehicles profitably through the shop, according to a recent survey conducted by Rotary Lift.

The vehicle lift manufacturer anonymously surveyed 327 U.S. shop owners about the trend toward faster cycle times. Of those surveyed, 70 percent reported that their average sales amount per shop ticket has increased over the past five years. At the same time, 46 percent reported that the average number of shop tickets their shops handle also has gone up during that time.

So, how are shops capitalizing on this increasing demand? Most of them (71 percent) are focusing on improving bay productivity and speed of service so they can handle more business.

Shop owners who answered Rotary Lift’s survey say they have taken various steps to achieve these goals. Many have installed faster service equipment. Others have automated customer paperwork, streamlined their services, redesigned the shop layout or changed staffing levels. Profits have increased as a result of these steps for 77 percent of shop owners surveyed.

The cost of doing nothing can be high, according to Rotary Lift. More than half of the shop owners surveyed said they have had to turn away business worth an average of $1,582 per month because they lacked the capacity to do the job. That represents a loss of nearly $19,000 in annual revenue. No wonder 92 percent of the shop owners surveyed said they would be interested in equipment that would enable their technicians to complete at least one additional job per week, especially if that equipment paid for itself within a few months.

“For most shops, the one piece of equipment they rely on more than any other is the vehicle lift,” says John Rylee, Rotary Lift director of marketing. “By making the lift faster and easier to use, we can help technicians work more quickly, improving bay productivity and, as a result, shop profitability. That’s the value proposition of our new Shockwave system — it turns Rotary Lift two-post and inground lifts into the world’s fastest lifts, making them twice as fast as other lifts.”

Shockwave-equipped lifts go up in just 25 seconds and down in 19 seconds, according to the company. Shockwave’s Spotline laser spotting guide and easy-set superstructures enable technicians to spend less time positioning the vehicle for service, so they can start and finish a job more quickly.

Time and motion studies have found that adding a Shockwave-equipped lift to a single bay can enable a shop to complete at least one additional job per week, for an additional annual profit of at least $3,259 (118 days payback).

For more information about Shockwave, contact your local Rotary Lift distributor, visit www.rotarylift.com/shockwave, or call (800) 640-5438.

HELLA Introduces HELLA BLADE LED 6” Series Auxiliary Lights

The HELLA BLADE Series combines powerful illumination with innovative features for the ultimate driving experience, the company said.

HELLA announced the introduction of its all-new HELLA BLADE LED 6” Series Auxiliary Lights, now available exclusively to the US and Canadian markets. Designed to meet the toughest demands of the most challenging off-road conditions, the HELLA BLADE Series combines powerful illumination with innovative features for the ultimate driving experience, the company said.

Transtar Announces Agreement for Axalta to Acquire The CoverFlexx Group

Axalta Coating Systems has signed a definitive agreement to acquire Transtar Holding Company’s subsidiary The CoverFlexx Group.

Bendix: Air Disc Brake Production has Doubled Since 2018

Commercial ADB adoption rates in Class 6-8 vehicles are now up over 50%, according to Bendix.

MPA: ‘We’re as Strong as Ever’

Chairman, President and CEO Selwyn Joffe discusses what he’d like the aftermarket to know about Motorcar Parts of America.

Dayton Parts Offers New Aftermarket Products

A new DPF differential pressure sensor, engine oil dipsticks and fuel injector wiring harnesses designed to match OEM spec.

Other Posts

Tint World Expands With First Ohio Location

Tint World Columbus is owned and operated by Josh Vanlandingham.

Hunter Engineering Releases Alignment Coverage for Hundreds of Vehicles

The release covers brand-new records – those not yet in existence at the time of the previous release – as well as updates to existing records, covering OEM changes to existing vehicles, the company said.

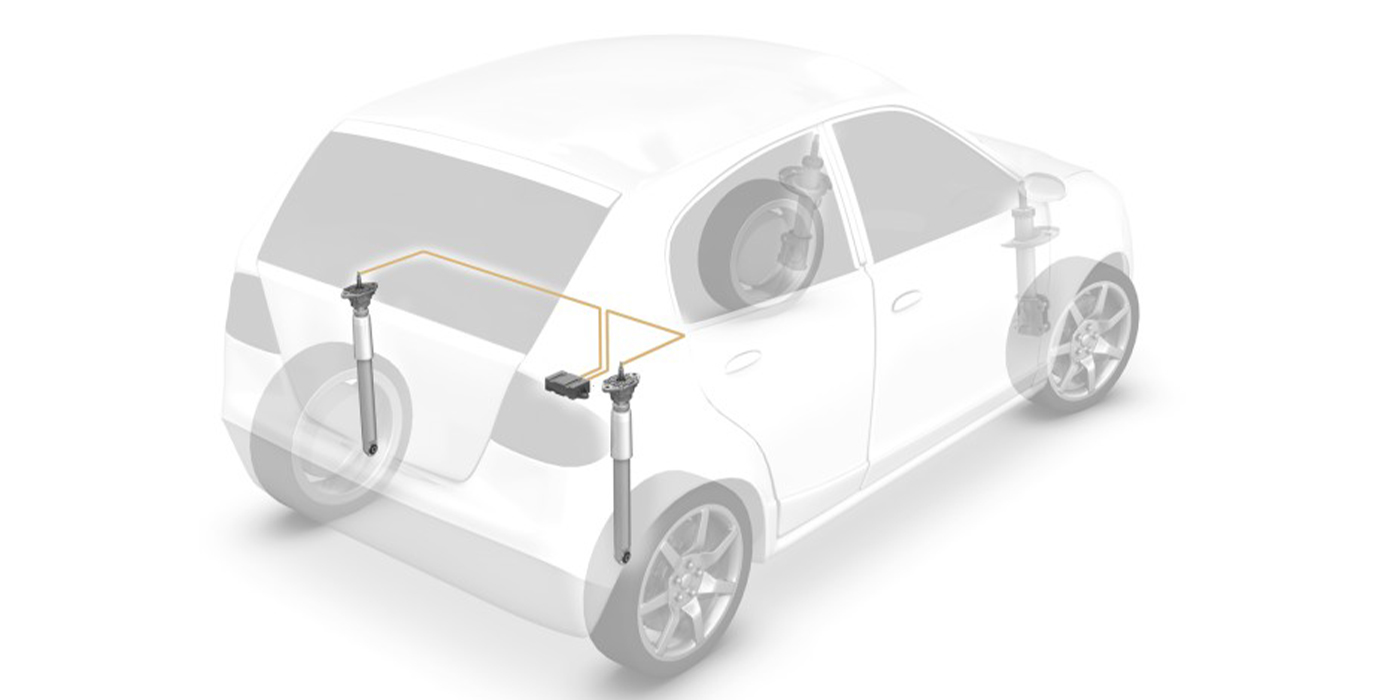

FCS Introduces 42 New Numbers in May

Complete strut assemblies, shock absorbers, shock absorber assembly kits and suspension struts for some of the most popular VIO applications are included in the release, FCS said.

USMW Releases New Fuel Pump Module Assembly

US Motor Works released Part No. USEP9214M, for several BMW applications.