With its latest innovation in cabin air filtration, Mann+Hummel is concentrating on a particle size that is becoming increasingly important – so-called ultra-fine particles (less than 0.1 micrometers). These can get particularly deep into the human body and cause harmful damage, the company said. The World Health Organization (WHO) is also paying particular attention to ultra-fine particles, and in its latest air quality guideline, it has called for this particle size to be included in routine measurements.

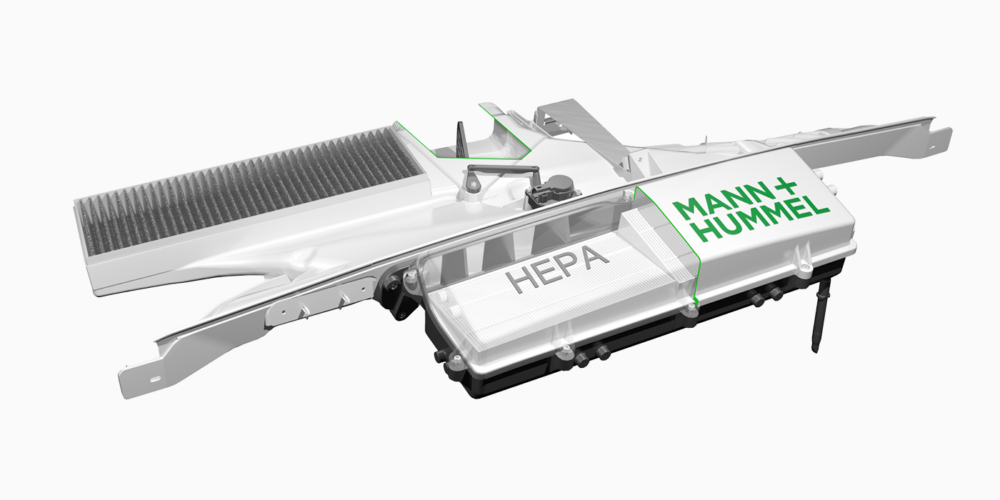

Regardless of the drive system, cabin air filters play a role in providing drivers and occupants with clean and healthy air. In electric vehicles, there is also a trend toward improving air quality through multi-stage filter systems That is why Mann+Hummel has developed HEPA filter systems to effectively protect people from these microscopic impurities. The abbreviation HEPA stands for high-efficiency particulate air.

“Our multi-stage cabin air filter systems with highly efficient HEPA filters offer protection through clean room quality air filtration, as is also the case in operating rooms, for example. Depending on the HEPA class, at least 99.95% of the particles are reliably removed from the air, including harmful bacteria, viruses and other microorganisms, even the previously mentioned ultra-fine particles,” said Christiane Michel, business development manager for cabin air quality at Mann+Hummel. “These are so small that they can easily penetrate into the bloodstream, cause severe damage to organs and be carcinogenic. We now know that more than 90 percent of the particles in the air are ultra-fine particles. Whether they are safe or not depends on their source and chemical composition.”

The company uses the HEPA filter as part of a three-stage system along with a pre-filter and a cabin air filter. Both can be equipped either as pure particle filters, in combination with activated carbon or as a third version with biofunctional and microbial coating. The particle filter uses a special non-woven material that efficiently retains dust, soot and pollen, while the activated carbon filter adsorbs harmful gasses and odors. A biofunctional coating binds allergens that can be released from pollen and provides additional protection against the growth of mold and bacteria on the filter medium.

Michel explained: “Since a HEPA filter can capture much finer particles than a conventional cabin air filter, its fiber structure is significantly denser, which results in significantly lower air permeability. To compensate for this, a HEPA filter has more media surface area and thus achieves the lowest possible pressure drop. In fact, the surface area of the filter media in our HEPA filters is about five times larger than in a conventional element, thanks to a smaller pleat spacing. It is, therefore, currently not possible to replace a standard cabin air filter with a HEPA element. Air conditioning systems are not built for these high-efficiency filters. Instead, the HEPA filter is located in a separate system – usually outside the air conditioning system – together with a pre-filter, as protection for the HEPA filter.”

Future Filtration Technology

Another future filtration solution from Mann+Hummel for the independent aftermarket is the reduction of particulate matter generated in road traffic. These particulate emissions include not only exhaust gasses, but also particles that enter the air as a result of braking and the wear of tires and road surfaces. The problem of particulate matter is independent of the drive system and also applies to electric vehicles. To prevent this particulate matter from entering the atmosphere, the company has developed a range of solutions to improve the particulate matter balance of vehicles. In addition to a brake dust particle filter that reduces brake dust emissions directly at the source, the company also produces a filter for the roof or underside of vehicles that collects particulate matter from the ambient air.

Cabin air filters will remain an essential component of future vehicles – regardless of the drive system. Up to 540,000 liters of air per hour can flow into a vehicle via the ventilator. In this way, pollutants can enter the vehicle interior from the outside and remain there for a long time – increasing the air pollution in the vehicle interior. This is precisely where multi-stage cabin air filter systems with their advantages come into play, the company said. This includes Mann+Hummel’s FreciousPlus with its biofunctional coating and protection against allergens, harmful gasses and particulate matter.

“Our goal for the future is to offer further cutting-edge technologies for inside the vehicle, such as digitally displaying the filter status and air quality in real time – for health and comfort in the vehicle,” said Michel.