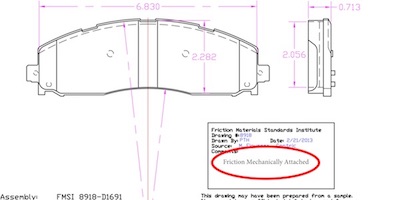

The Friction Materials Standards Institute (FMSI) has updated its database to include information on whether the original brake pads from the OEMs utilize mechanical attachment methods to secure the friction material to the backing plate.

FMSI has identified 42 D-numbers (brake pad part numbers) that come from the OEMs with mechanical attachment. The part numbers and associated applications represent about 30 percent of the cars, trucks and school buses on the roads in North America.

“FMSI is in year two of an aggressive five-year plan upgrading and modernizing our operating systems,” said Frank Oliveto, president of FMSI. “Ahead of our plan, we are heavily investing in new systems and technologies to enhance and expand information, protecting our intellectual property and improving the user experience for our members.”

Members of the Global Brake Safety Council (GBSC) have said they are encouraged that this information is now being shared with North American aftermarket brake pad manufacturers and suppliers that utilize the FMSI numbering system.

Mechanical attachment for brake pads should be treated very seriously, as it is very similar to rebar in concrete, according to the GBSC. Just like rebar-reinforced concrete, you cannot see the mechanical attachment in a brake pad.

Mechanical attachment is required on specific applications for high loads where adhesive alone would lead to pad failure in OEM testing. This recognition by FMSI and industry-wide awareness will help improve the safety and quality of aftermarket brake pads across North America, says the council.

According to a recent technical bulletin from the GBSC, mechanical attachment is specified by OEMs to meet performance and safety requirements for a vehicle platform. The replacement brake pad needs to duplicate the mechanical attachment feature for these applications by aftermarket pad manufacturers, the bulletin specifies. Removing the mechanical attachment feature will compromise the structural integrity of the entire brake system, the council states.

GBSC also encourages businesses selling brake pads in the North American aftermarket to join FMSI. FMSI’s mission is to collect, characterize and communicate to FMSI’s members the vehicle manufacturer’s OE service product and include this product information in the FMSI and FMS standardized part numbering system. Established in 1948, FMSI was founded as a trade association of automotive aftermarket friction manufacturers with the goal of creating a standardized part numbering system for brakes and clutch facings. From manufacturer through shops one part number is used as the standard and as a common language – the FMSI number.

Membership in FMSI is open to any manufacturer of friction and related products covered by the trademarked FMSI and FMS part numbers. Other participants in this industry may be eligible for licensee membership. Go to fmsi.org to gain access to their numbering system and this critical information.

To learn more about the Global Brake Safety Council (GBSC), visit gbscouncil.com.