Whether it is to mitigate the impact of climate change or simply to do right by the environment, many consumers and businesses are looking for ways to be more sustainable. Sometimes, however, enthusiasm can wane if sustainability is perceived as providing lower-quality or higher prices as compared with more traditional options.

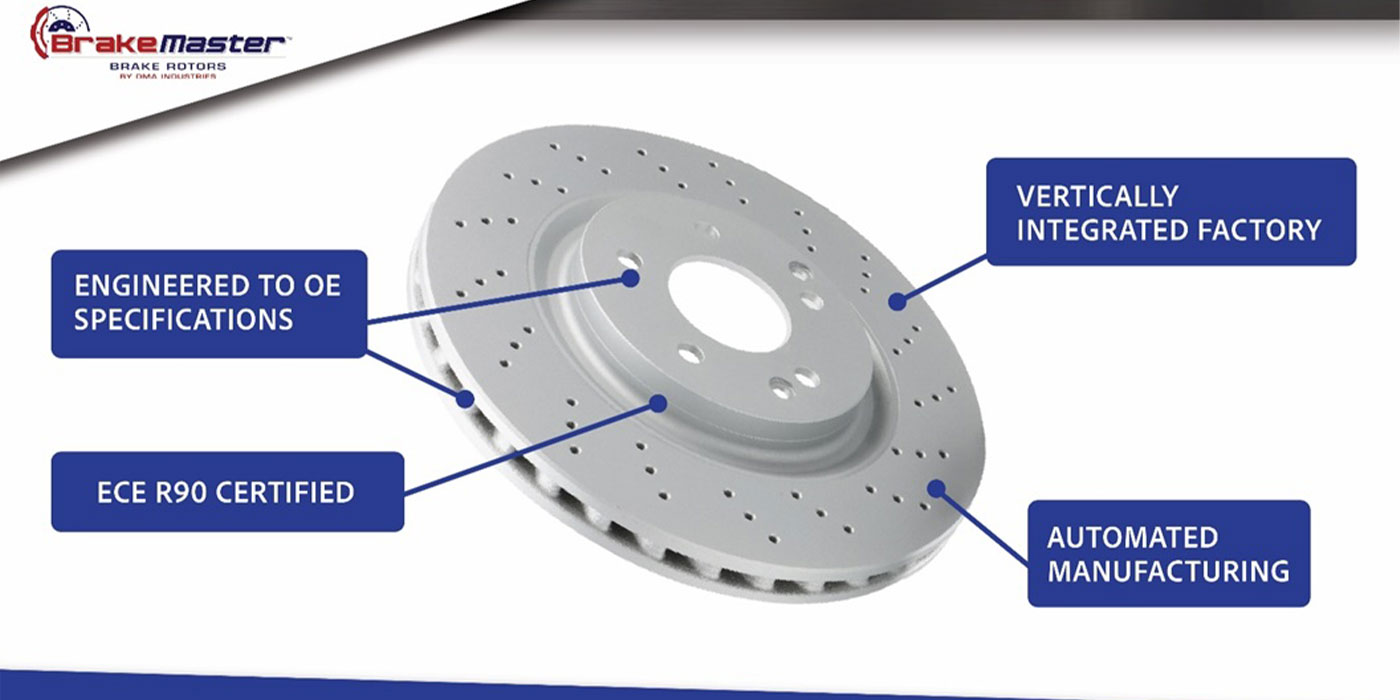

Fortunately, motorists who purchase remanufactured parts do not need to compromise quality or price. Not only do remanufactured aftermarket parts offer consumers a more sustainable option when repairing their vehicles, they also provide exceptional value. Leading remanufacturers go to great lengths to offer parts that are equal to OE in terms of performance, and often superior due to reverse engineering and testing. In short, remanufacturing is a sustainable process, not the same as simply repairing or refurbishing units.

The Remanufacturing Industries Council defines reman as “a comprehensive and rigorous industrial process by which a previously sold, leased, used, worn, remanufactured or non-functional product or part is returned to a like-new, same-as-when-new or better-than-when-new condition from both a quality and performance perspective, through a controlled, reproducible and sustainable process.”

Let us talk about what this means for shops that choose reman parts to repair their customers’ vehicles.

Leading remanufacturers follow strict protocols for inspecting, disassembling, cleaning, and reconditioning or replacing components, as well as testing the remanufactured units against OE-tolerance specifications. The core for a remanufactured part is completely disassembled down to individual components. All renewable components are cleaned and analyzed for failure modes, and then reassembled using a combination of operative, refurbished or new components — resulting in a high-quality finished product virtually identical to a new part. Remanufacturers also might address known OEM design issues — utilizing upgraded components that improve upon the original design.

Remanufacturing employs many of the same manufacturing techniques as the production of new components, but the reman process consumes dramatically less energy and fewer resources to produce an equivalent product than building one from scratch.

The Heart of the Reman Economy

Often, we read that Europe leads the United States in terms of green initiatives – but remanufacturing is not one of those cases. According to Rematec, the United States is the world’s leading manufacturer, consumer, and exporter of remanufactured goods. Measured by revenue, the market for remanufactured auto parts in the United States is $5.8 billion, according to IBISWorld.

As part of the automotive industry, we are in the heart of the reman economy. Rematec estimates that two-thirds of all remanufacturing activities are performed in the remanufacturing of motor-vehicle components. A large number the world’s leading auto parts remanufacturers are headquartered in the United States.

Alternators, starters, brake calipers and brake boosters are among the remanufactured items available in the automotive aftermarket. For motorists, these, and other remanufactured parts, represent an excellent economic value for a like-new or better product. Equally important are the green benefits of remanufacturing: energy conservation, a reduction in manufacturing waste and encouraging the recycling of raw materials – all of which are good for our planet.

Brought to you by Motorcar Parts of America (MPA).