Further leveraging technology building blocks from its parent companies, Nexteer Automotive and Continental Automotive, CNXMotion expands its Brake-to-Steer (BtS) technology with two new software functions that provide backup safety layers for all variants of Electric Power Steering (EPS) and Steer-by-Wire (SbW) systems and across all SAE levels of driving automation (levels 1 – 5).

CNXMotion’s BtS technology portfolio includes:

- Driver Effort Support: SAE Levels 1-3 – NEW

- Steer-by-Wire Support: SAE Levels 1-5 – NEW

- Automated Driving Support: SAE Levels 4-5 (launched in 2020)

“These new Brake-to-Steer software functions further enable safety redundancies across all electric power steering applications and SAE driving levels without the cost and complexity of additional hardware,” said Greg Katch, general manager, CNXMotion. “Our advanced Brake-to-Steer technology can help ensure the safety net is always on through driver effort support and steer-by-wire support, as well as automated driving support.”

Brake-to-Steer Driver Effort Support

EPS systems are designed with multiple protective layers to ensure the steering safety net is always on. When paired with a traditional EPS system, BtS Driver Effort Support adds another safety layer and can provide up to an additional 25% reduction in torque. While steering traditionally manages the lateral control of a vehicle, BtS enables the braking and powertrain systems to contribute to lateral control to reduce steering efforts, when necessary, the company says.

Brake-to-Steer Steer-by-Wire Support

SbW replaces the mechanical steering connection between the hand wheel and road wheels with algorithms, electronics and actuators. In this type of steering system, the BtS SbW Support function adds another safety layer by translating the driver’s steering inputs into brake system control of the vehicle’s lateral motion.

Brake-to-Steer Automated Driving Support

Launched in 2020, CNXMotion’s original BtS function pioneered the use of electronic braking as an additional layer of steering control for traditional, highly automated and autonomous vehicles (SAE Levels 4–5). This BtS function earned an Automotive News PACEpilot Innovation to Watch in 2021.

“Brake-to-Steer’s expanded software functions highlight how collaboration through our CNXMotion joint venture with Continental leads to innovation in motion control solutions and further enhances the steering safety net for all assisted and automated driving levels,” said Robin Milavec, president, chief technology officer, chief strategy officer and executive board director, Nexteer Automotive. “When combined with Nexteer’s industry-leading, advanced steering systems like Steer-by-Wire or High Availability EPS, Brake-to-Steer provides OEMs with a cost-efficient, flexible way to add yet another layer of safety and redundancy.”

Brake-to-Steer Benefits for Drivers & OEMs

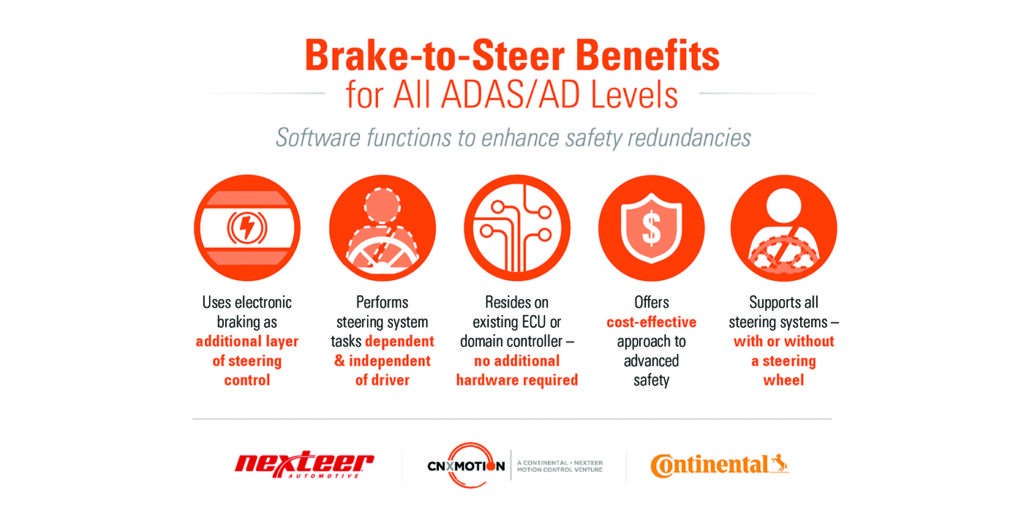

Value: Leverages the vehicle’s existing steering, braking and powertrain systems. The portable software functions can reside on an existing controller – eliminating the cost of any additional hardware.

Flexibility: Provides an additional layer of vehicle safety and redundancy on all vehicles with EPS and SbW. The three BtS software functions cover all types of vehicles with or without a driver.

Safety: Enhances safety through an additional layer of steering redundancy.

“As the industry progresses toward highly automated and autonomous vehicles, Brake-to-Steer’s advanced functions allow for critical safety features across all levels, enabling increased safety for all road users,” said Lutz Kuehnke, head of Safety and Motion Business Area, Continental Automotive, North America. “CNXMotion’s Brake-to-steer technology offers a flexible and cost-effective way to achieve and to prioritize safety needs by leveraging existing systems in the vehicle, e.g., Continental’s 1-box brake controls unit MKC1, and eliminating the need for additional components.”