Penray Inc. has introduced its new cleaner for mass air flow (MAF) sensors, part No. 2520. While there are other MAF sensor cleaners on the market, this new formula is designed to be plastic-friendly, according to Penray.

Penray Inc. has introduced its new cleaner for mass air flow (MAF) sensors, part No. 2520. While there are other MAF sensor cleaners on the market, this new formula is designed to be plastic-friendly, according to Penray.

The delicate fine wire that senses the flow of air entering the induction system is subject to contamination. Dust, oily vapors and other contaminants can collect on this very fine wire, forming a layer of insulation that can cause it to provide inaccurate information to the car’s engine management computer.

Results of a contaminated MAF sensor manifest themselves as rough idle, hesitation, poor gas mileage and, in many cases, the appearance of a Check Engine light. The cost of new replacement MAF sensors can run as much as $400 or more. So, the use of an effective cleaning product is a viable alternative and a valuable service to the customer, Penray explains.

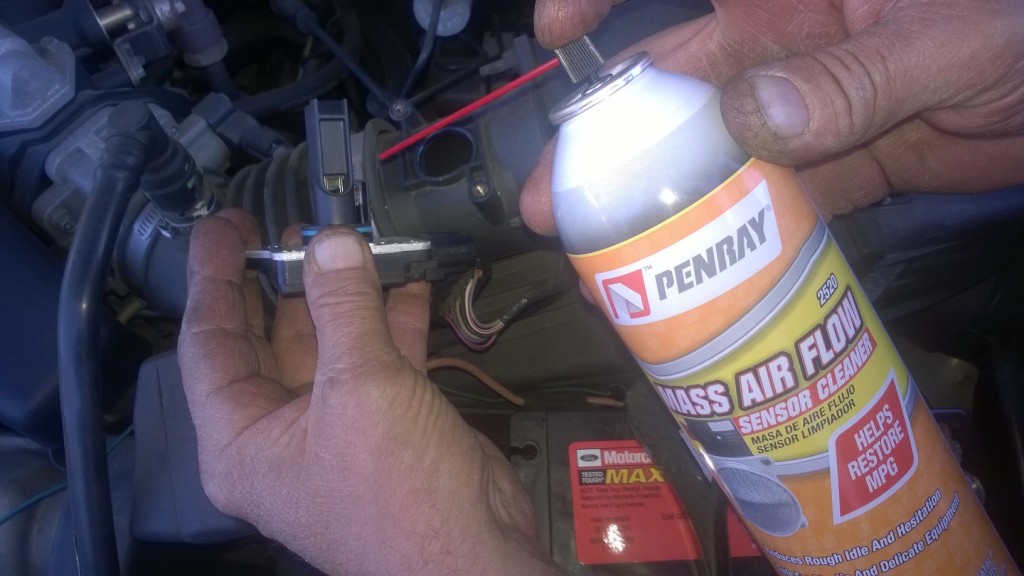

The attachment point for the Mass Air Flow Sensor is usually a small plastic clip. Often, aggressive solvents like typical carburetor cleaners can damage delicate plastic pieces. Penray No. 2520 is specially formulated to effectively clean the sensitive component without harming plastics, coatings or adhesives, the company says.

Use of Penray’s MAF sensor cleaner was designed to be easy. The sensor element is typically accessed by unsnapping a few retaining clamps and lifting off a piece of plastic ductwork to reveal the fine sensor wire. This wire is very fragile and it is difficult not to cause damage when touching it, Penray adds. Once the sensor is removed from the duct, several sprays of Penray 2520 will quickly dissolve deposits, so the full length of the wire is once again free of contamination, the company points out. Newly exposed to the rush of incoming air, the sensor is able to perform its job properly and accurately, according to Penray.

“Poor engine performance or degraded fuel economy can often be traced to a contaminated MAF sensor fine wire, especially when it reaches the point where it causes a Check Engine light to illuminate,” said Mark Kardon, Penray’s director of marketing. “Adding the use of this simple-to-use product to routine maintenance restores the performance of the wire and sensor, preventing the huge expense of a new sensor assembly.”