PUNE, India – Dana this week dedicated the company’s 90,000-square-foot technology center in Pune, India. Home to more than 240 engineers, this facility is strategically equipped and located to offer world-class engineering capabilities to original equipment manufacturers in the light-vehicle, commercial-vehicle and off-highway markets in India and throughout the region.

The Dana India Technical Center is the company’s 13th facility in India, further expanding Dana’s footprint in the region to support future growth. Dana employs more than 2,900 people in India, including those operations in which the company holds a joint interest.

"India is a vital market that propels economic growth throughout the Asia Pacific region, and our investment in that country over the past half century demonstrates our commitment to and confidence in the region," said Dana President and CEO Roger Wood. "The Dana India Technical Center allows us to offer our customers unmatched local technical expertise and a direct connection to our industry-leading global engineering resources."

Dana customers in India include: Ashok Leyland Ltd., Caterpillar India, Deere and Co., Force Motors, Ford India, General Motors India, Mahindra & Mahindra, Mahindra Trucks and Buses Ltd., TAFE, Tata Motors and VE Commercial Vehicle Ltd. Export customers include Caterpillar, Ford, Land Rover, Nissan, Renault, Still and Toyota.

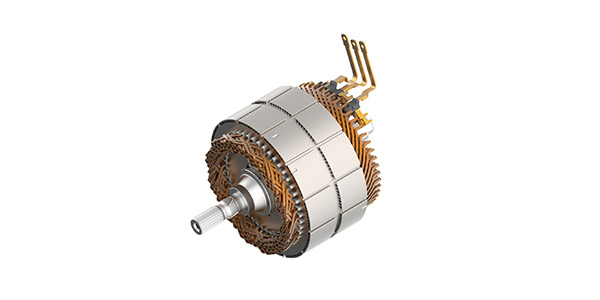

Devoted to the research, design, development and testing of drivetrain, sealing and thermal-management products, the Dana India Technical Center is fully integrated into Dana’s global research and development system to support new products from concept development through launch, as well as to adapt technologies developed elsewhere in the world for the specific needs of the Indian market.

The center combines design, finite element analysis and testing for all of Dana’s product groups under one roof. It includes an electronic controls lab, a testing area, a materials development lab, a prototype area and an NVH and performance analysis lab for product development.

The new lab in Pune features the latest testing equipment for axles, transmissions, materials, NVH, prototyping, inspections and machining to ensure that products engineered and manufactured by Dana in India meet the company’s highest standards for performance and durability. This equipment includes dynamometers, a rotating bending test stand, a beam fatigue test stand, a multi-axis spin stand, rotary actuators and linear actuators.

"For decades, we have worked side-by-side with leading vehicle and equipment manufacturers in India, and by locating a full range of engineering resources here, we can deliver drivetrain solutions as much as 12 months quicker than our competitors," said George Constand, Dana’s chief technical and quality officer. "With this new facility, we can rapidly deliver customized solutions that accommodate local needs and requirements for optimizing total cost of ownership, enhancing vehicle efficiency and addressing environmental concerns."

Dana adds that it has demonstrated the value of local engineering and OEM support through the development of the Spicer Rui Ma brand of off-highway transmissions and axles. Supported by the Dana China Technical Center in Wuxi, Spicer Rui Ma drivetrain solutions provide an optimized blend of product features, performance, dependability and cost demanded by purchasers of the majority of construction and other off-highway vehicles manufactured in China today, the company stated.

Likewise, the company says the Dana India Technical Center will offer advanced technologies and product lines designed in India, for India.

Philips Ultinon Drive 5000 LED Lightbar Line Expands

Lumileds has expanded the Philips Ultinon Drive 5000 series to include eight models.

Lumileds has expanded the Philips Ultinon Drive 5000 series of LED lightbars to include eight models. The series now includes 10,” 20,” and 30” lightbars available in single- and double-row versions, and 40,” and 50” lightbars available in double-row configurations.

All have been built for off-road use, with scratch-resistant polycarbonate lenses, DT waterproof electrical connections, and corrosion-free, stainless steel mounting brackets, Lumileds said. Ultinon Drive LED Lightbars are engineered with single-piece assemblies that allow them to achieve an IP68 / IP69K rating for resistance to high pressure water and dust and an IK07 rating for resistance to impacts.

Continental Releases 67 New Part Numbers

Twenty-two new import part numbers, as well as 39 new pulley and tensioner part numbers, are immediately available.

B’laster Holdings Launches B’laster Refrigerants Line

The product lineup was created to service and maintain both R-134a and R-1234yf automotive A/C systems, according to B’laster Holdings.

Schaeffler Group USA Expands Product Portfolio

Seventy new parts have been added to the INA, LuK and Schaeffler Bearings portfolios in the first quarter of 2024.

Anchor Adds More BMW, MINI Coverage

The new products cover more than 1,994,760 applications and model years 2016-2024.

Other Posts

Continental Marks 15 Years in Thailand, Five Years of Tire Production in Rayong

Continental’s Rayong plant has an annual production capacity of 4.8 million tires and employs around 900 people.

Global EV Sales Expected to Increase by 21% in 2024

This represents a significant decline from growth rates of 31% in 2023 and 60% in 2022, ABI Research said.

Geotab: UK’s Most EV-Suitable Market in Europe

By going electric, British private and public sector organizations could reduce the TCO per vehicle by $16,341 over seven years.

Neusoft Launches Global In-Vehicle Intelligence Solution

OneCoreGo 5.0 made its debut at Auto China 2024 and aims to enhance in-vehicle experiences with AI-driven solutions.