WICHITA, Kan. – Universal Lubricants, a leader in sustainable energy solutions that collects used waste oil and turns it into crystal-clear re-refined base oil, has now trademarked that base oil as "EcoClear." This action is part of the company’s ongoing campaign to encourage environmentally responsible lubricant recycling.

Lubricant base oil is one of the most valuable components in a barrel of crude oil, according to Universal Lubricants. While many components of crude oil such as gasoline, jet and diesel fuels are "lost" after combustion, lube base oil does not wear out. Drained from automobiles, industrial vehicles, heavy-duty engines, aircraft and railroad engines during oil changes, the oil can be recovered and re-refined to a quality equal to or better than its original virgin form by using an advanced re-refining process, the company says.

"Like Rumpelstiltskin of the fairy tale, you might say we spin straw into gold," Universal Lubricants CEO Jan Horsfall said. "Our closed loop process is a self-contained, self-sufficient system. Each year we collect more than 40 million gallons of used oil from our customers across the country and deliver it to our state-of-the-art re-refinery in Wichita, Kan. There, we remove the depleted additives and impurities in the used oil to produce the clean, API licensed Group II base oil now known as EcoClear. That base oil is then blended with high-performance additives to produce our Eco Ultra line of high-quality lubricants. It’s a process we can repeat over and over again for as long as people use oil."

Built in 2009, Universal Lubricants’ Wichita re-refinery uses a sophisticated hydrotreating process licensed from Irvine, Calif.-based Chemical Engineering Partners (CEP), an advanced process technology company that provides re-refining technology, process simulation, consulting services and technology designs to clients worldwide. The process was developed over many years and Universal Lubricants says it continues to benefit from the latest CEP process advances.

"Our re-refinery runs 24/7, every day of the year," said Drew Doggett, lead operator at the Universal Lubricants re-refinery. "We re-refine millions of gallons of used oil in order to produce higher performance products. We’re proud that what we do creates a more independent U.S.A. by reducing the amount of foreign crude our country needs to import."

CEP President Joshua Park, who designed Universal Lubricants’ Wichita facility, said the company stands out in its commitment to both product quality and environmental stewardship.

"Universal Lubricants’ closed loop process is the complete package," Park said. "Their ownership from collection, to refining, blending and distribution makes the Eco Ultra line of lubricants one of the best in the world. While other companies often outsource their blending and servicing operations, Universal Lubricants maintains complete control over every aspect of the process, guaranteeing quality."

Last week, the company announced that its Eco Ultra Synthetic Blend Motor Oil was awarded a dexos1 license for meeting the rigorous quality requirements for use in the newest General Motors (GM) gasoline engines.

Horsfall said the Universal Lubricants team is dedicated to educating and encouraging consumers to choose eco-friendly motor oils and to recycle used oil to protect the environment and the economy.

About 1.3 billion gallons of oil are used in the U.S. each year, but only about 10 to 15 percent of that oil is repurposed. Re-refining used lubricants requires up to 89 percent less energy and releases up to 65 percent fewer harmful emissions than refining from crude. Putting used lubricants into the re-refining cycle also eliminates the danger that comes from improper disposal. It is estimated that one gallon of improperly disposed motor oil can contaminate one million gallons of ground water.

"If all 308 million Americans got an Eco Ultra oil change, we could prevent 616 million barrels of crude oil from being extracted from the earth," Horsfall said. "Our customers have the unique opportunity to use high-quality finished products that are derived from re-refined EcoClear base stocks, which will lower dependency on foreign oil, reduce depletion of natural resources and eliminate waste material. Now that’s environmental stewardship."

For more information about Universal Lubricants’ closed loop quality standards and Eco Ultra products, visit www.ecoultraoil.com.

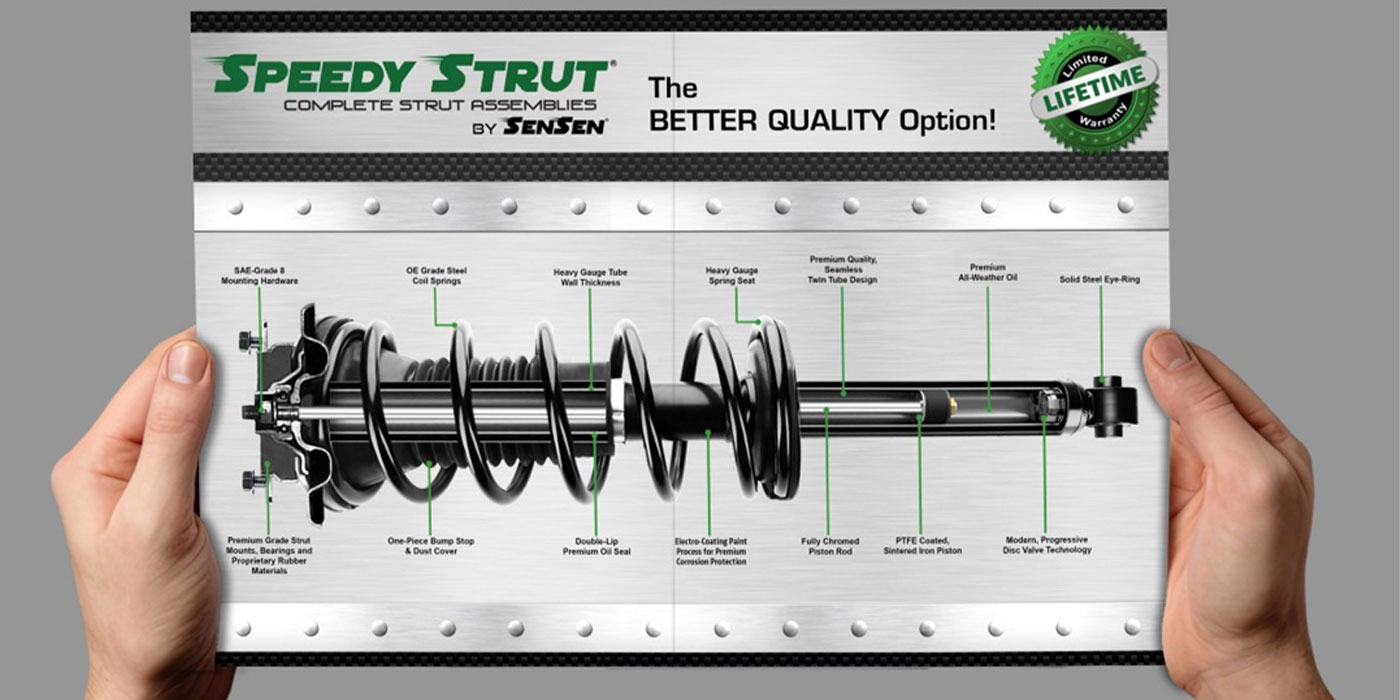

PRT Launches 59 New Complete Strut Assemblies

Extending PRT’s product portfolio in North America, the new release represents nearly 12M vehicles in new coverage.

PRT announced the launch of 59 new complete strut assemblies for the North American market.

The launch includes application coverage for Nissan Frontier, Toyota Highlander and Mercedes E-Class models, in addition to brand-new applications, such as the Dodge Durango 2022, the Ram ProMaster City 2022, and the Mazda CX-9 2022, among others, according to PRT.

SMP Releases 2023 Corporate Sustainability Report

The report provides insight into the company’s initiatives, future goals and achievements, Standard Motor Products said.

GSP Announces New May Part Numbers

The units released in May are in stock and ready to ship, GSP said.

Cooper Standard Issues Corporate Responsibility Report

Titled “Commitment to Excellence,” the report provides updates on key sustainability targets, initiatives and ambitions.

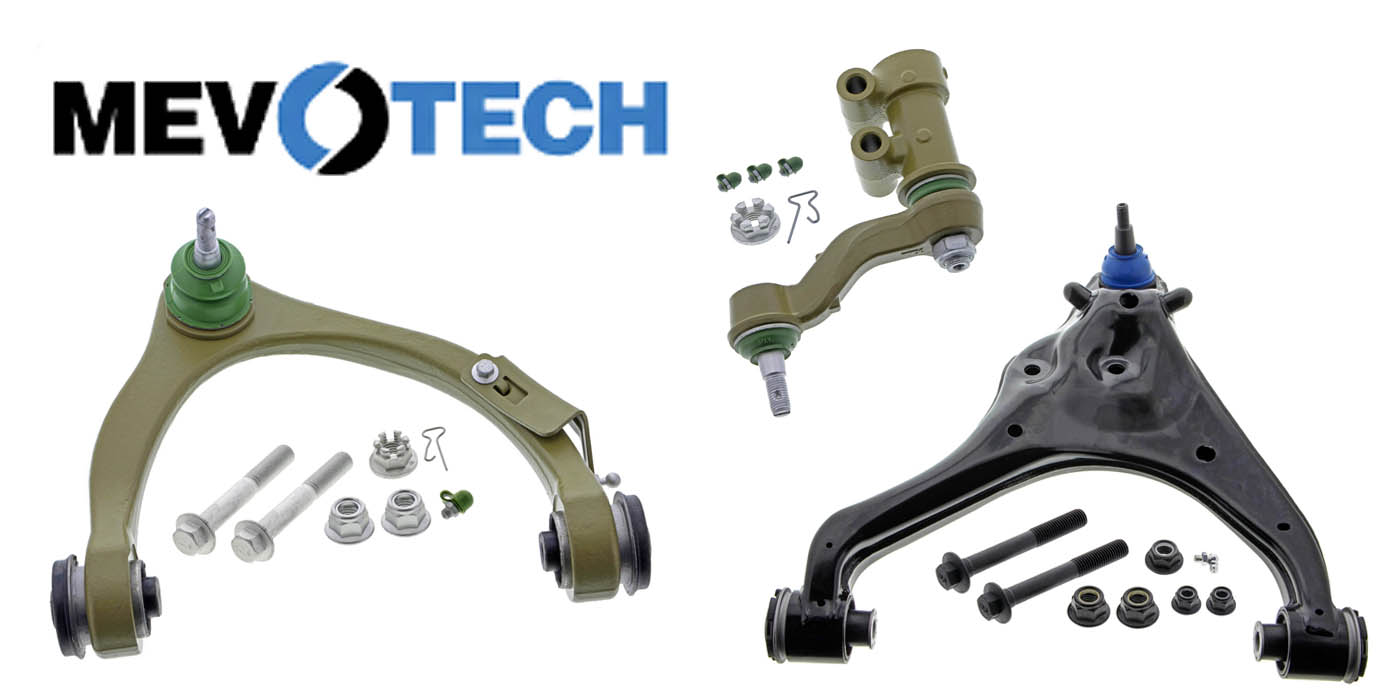

Mevotech Expands Coverage with 188 New Part Numbers

The release covers domestic and import passenger vehicles, pickup trucks, vans, SUVs and EVs, up to the 2023 vehicle model year.

Other Posts

MAHLE Finalizes Sale of its OEM Thermostat Business

As part of the transaction, ADMETOS is taking on around 600 employees in six countries.

ZF Aftermarket Releases 36 New Parts for US, Canada

ZF has introduced a total of 185 new products in 2024 under the ZF, LEMFÖRDER, SACHS, TRW and WABCO brands.

Dana Expands Spicer ReadyShaft Assembly Coverage

The addition of more than 3,000 new part numbers brings Dana’s ReadyShaft program

to over 13,000 active SKUs.

Litens Aftermarket North America Elevates Sustainability Efforts

Litens said it is dedicated to achieving carbon neutrality by 2030.