The joint development agreement (JDA) between GRIPMetal, a subsidiary of NUCAP Industries and the key technology behind NUCAP Energy, and Sumitomo Bakelite Co. Ltd. to develop innovative, lightweight composite solutions to industrial challenges has resulted in applications previously believed to be “out of reach” for composites.

Brake Backing Plate

NUCAP, which also includes innovative brake producer NRS Brakes, has used Thermoset Composite, developed by Sumitomo Bakelite Co., Ltd.(SBCL) in producing new components.

Saving weight dominates the design and development process for all types of vehicles because lighter weight components mean better fuel economy, fewer emissions and a smaller carbon footprint.

In addition, lighter weight, especially in suspension components like brakes, results in a better ride.

“Electric vehicles, with their need for maximum range between charges, put a premium on these lightweight components, so a 30-percent reduction in un-sprung mass,” said Montu Khokhar, CEO of NRS Brakes. “This new hybrid brake-backing plate developed by us under the JDA with Sumitomo can provide auto engineers with a solid solution to one of their key weight challenges.”

Additional benefits of this design include:

- Lifetime corrosion resistance – both the composite and galvanized steel plates are corrosion resistant;

- Improved noise/vibration/harshness (NVH) resistance – lower modulus of composite provides dampening effect of vibration from the brake rotor; and

- The lightweight backing plate is currently being evaluated by several U.S. and Japanese manufacturers for use in both passenger and commercial vehicles.

Electronics Heat Shield

Electronics and electric motors are being increasingly utilized in every area of the vehicle for control and actuation. When used in close proximity to high heat sources such as the exhaust or engine, in order to maintain the function of the electronics, they need to be maintained within the specified operating temperature range. This is essential for designers who are also looking to reduce the package space of assembled systems.

SBCL has developed a new innovative heat shield that reduces both radiated heat and conducted heat with a unique hybrid design which maximizes the benefits of two materials:

- Phenolic composite, which utilizes its high heat capacity to absorb 90% of the heat and can be molded in thin wall sections to reduce package space.

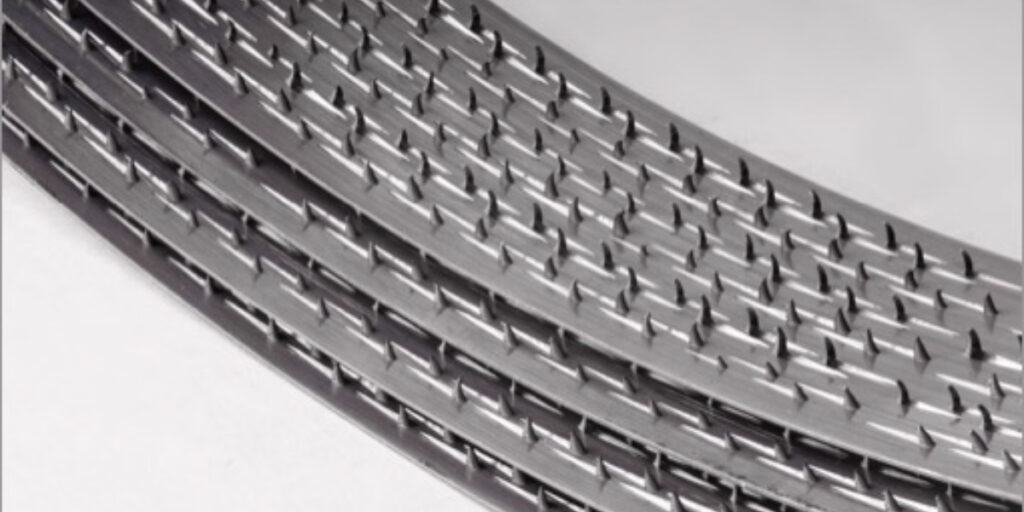

- Aluminum sheet, which reflects heat and, with a GRIPMetal finish, enables low-cost heat shield manufacturing. It also has the ability to be directly molded using a mold-forming process pioneered by SBCL.

In a recently launched mid-engine high performance vehicle, the hybrid design heat shield was able to reduce the temperature of the electronic module by 50F – and maintain continuous operation of critical electronics in the exhaust system – when exposed to constant temperatures over 600F.

“SBCL’s high heat and flame-resistant material technology is enabling electronics to be directly integrated into harsh environment applications such as EV motor and battery pack, which deliver higher durability, lower weight and lower cost than traditional solutions,” said Seiji Suzuki, CEO at Sumitomo Bakelite North America.