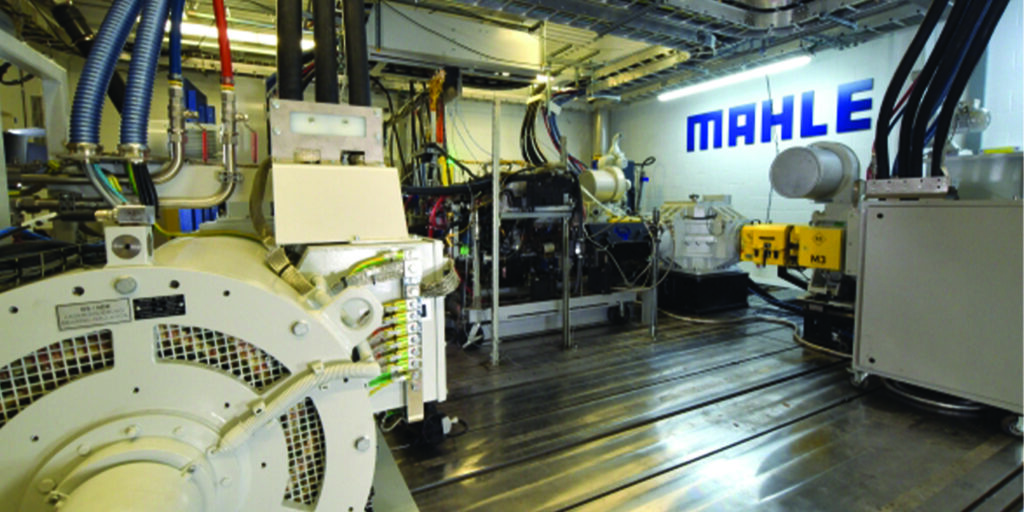

MAHLE Powertrain is investing $4 million in a new powertrain dynamometer facility in Plymouth, Michigan, aimed at accelerating vehicle development as manufacturers continue the shift toward electrified vehicles. Capable of supporting full powertrain development, from the testing and calibration of individual drive components to the complete driveline systems of complex four-wheel-drive vehicles, the new facility is unique in North America in handling the demands of even the highest-performance light- and heavy-duty hybrid and electric vehicles, the company says. The new facility enables Advanced Driver Assistance System (ADAS) technology assessments, U.S. and European emissions testing capability, and drivability development testing all on the same testbed and will be ready for operation in the third quarter of 2022.

“We are delighted to announce this latest addition to our powertrain testing facility,” said Hugh Blaxill, managing director of MAHLE Powertrain USA. “This investment underscores our determination to provide world-class services to our clients through the provision of state-of-the-art facilities and expertise. The new facilities will extend our unique capabilities to cover client requirements both in the U.S. and globally and will prove an invaluable resource for light-duty and heavy-duty manufacturers alike. “Crucially, this means we are able to conduct a significant amount of development and validation work without requiring a large number of prototype vehicles to be built by the manufacturer.”

The new test facility, located at MAHLE Powertrain’s engineering center in Plymouth, Michigan, will work alongside the existing chassis dynamometer and will support all aspects of hybrid and battery-electric vehicle development.

By enabling the early assessment of various powertrain layouts and allowing testing to be conducted before a completed chassis is available, the new facility will help manufacturers to significantly shorten the overall development cycle.

As well as full powertrain testing and calibration work, the facility will enable the development of powertrain systems, the calibration of transmissions, hybrid and battery-electric powertrain configurations, Real Driving Emissions (RDE) measurements and electric vehicle range determination.

The state-of-the-art testbed will even support the testing and evaluation of ADAS technologies including LiDAR and RADAR sensor packs, and will feature climatic conditioning down to -10°C or up to +40°C.

The company says this new facility exceeds the specifications of the highest-performance electric vehicles on the market, with the capability of handling up to 7,000Nm of instantaneous torque per wheel with an average torque response time of 0.5ms. The dynos are supported by a 623kW battery emulator with future expansion capacity to more than 1MW. These features coupled with a maximum wheelbase of 4.5m make the facility unique in accommodating even the highest output pickups and cargo vans.

The new facility is expected to be ready for operation in the third quarter of 2022 and is likely to be in high demand, with several premium automotive manufacturers already requesting time allocations.

For more information on the full capability of the new powertrain dyno facilities, click here.