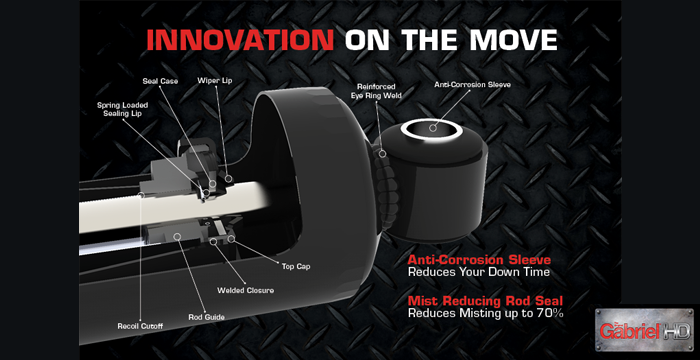

Gabriel Ride Control LLC has developed an improved misting reduction seal for its heavy-duty shock products, aimed at extending service life and reducing overall downtime for maintenance. The enhanced seal is now available in the company’s FleetLine commercial truck, trailer and bus shocks and GasSLX adjustable shocks.

“We wanted to solve one of the main problems that fleet operators believed to be an inevitable headache: oil escape from shock absorbers,” said Joan McMath, director of OE, service and heavy-duty sales at Gabriel. “With the introduction of the enhanced misting reduction seal technology to our GasSLX and FleetLine products, we have proven that it is possible to reduce misting significantly in shock absorbers, and therefore to keep customers’ fleets on the road more consistently.”

“We wanted to solve one of the main problems that fleet operators believed to be an inevitable headache: oil escape from shock absorbers,” said Joan McMath, director of OE, service and heavy-duty sales at Gabriel. “With the introduction of the enhanced misting reduction seal technology to our GasSLX and FleetLine products, we have proven that it is possible to reduce misting significantly in shock absorbers, and therefore to keep customers’ fleets on the road more consistently.”

The demanding conditions present in heavy-duty vehicle applications cause misting in all shock absorbers over time. Misting occurs when the oil within the shock absorber, critical to ride control performance, slowly leaks out of a seal in the product, coats the outside of the shock absorber and accumulates dust and debris. This oil escape causes diminished shock absorbing capabilities and eventual product failure.

With Gabriel’s improved misting-reduction seal technology, oil escape can be reduced by up to 70 percent over time. This leads to extended service life for the company’s heavy-duty shock absorbers, as well as improved performance over time.

Visit gabriel.com for more information.