CANTON, Ohio – After securing a new five-year labor agreement, officials at The Timken Co. announced they will move forward with a $225 million investment at the Faircrest Steel Plant in Stark County, Ohio. With this investment, the specialty alloy steel manufacturer says it will improve productivity, expand its product range and increase capacity to serve growing demand for Timken specialty alloy steel bars.

"This is a good day for our customers around the world, for our company and for the local community," said Salvatore Miraglia Jr., Timken president – steel. "We’ve received great support for our steel expansion from state and local officials and suppliers, and now our employees have put the last element in place to make this project a go."

Timken said ratification (completed yesterday) of a new extended labor agreement between the company and members of United Steelworkers (USW) Local 1123 establishes workforce stability through project construction and startup in 2014. The labor agreement covers four facilities in Stark County through September 2017 and replaces an agreement that would have expired in the midst of the project’s start-up in 2013.

"We are seeing growing demand for Timken specialty steel to support the most demanding energy and industrial applications," said Miraglia. "This is the right time to make the kind of investment that will improve our operating performance while also expanding our capacity and size range for these products. Combined, that will strengthen our ability to serve these important industries and position the business for continued profitable growth and greater shareholder value."

A new ladle refiner and large-bloom continuous caster are central to the productivity gains from the investment. The new equipment also is expected to increase the Faircrest operation’s shippable capacity by 25 percent and enable the production of a broader range of large-diameter bars.

"We have a highly skilled, capable workforce committed to continuous improvement," said Thomas Moline, vice president of steel manufacturing. "Our team understands what it takes to make custom-melted, high-quality alloy bars and tubes that meet our customers’ exacting metallurgical requirements. This investment, which is the largest since opening the plant in 1985, builds on those skills to improve our productivity, while giving us the ability to offer even more to the customers who rely on us for their own success."

Timken, known for the reliability of its power transmission products that include bearings, gears and related components, cites its century-long steelmaking expertise as a key competitive differentiator. In 2011, the Timken steel segment melted 1.7 million tons of raw materials to generate $2 billion of sales of its custom-designed steel. To further productivity and growth, the company invested more than $200 million in its steel operations in northeast Ohio in the past five years. The most recent of those investments included a $35 million high-volume in-line forge press at the Faircrest rolling mill, which is under construction, and $50 million in capital improvements at its Harrison and Gambrinus steel plants.

HELLA Introduces HELLA BLADE LED 6” Series Auxiliary Lights

The HELLA BLADE Series combines powerful illumination with innovative features for the ultimate driving experience, the company said.

HELLA announced the introduction of its all-new HELLA BLADE LED 6” Series Auxiliary Lights, now available exclusively to the US and Canadian markets. Designed to meet the toughest demands of the most challenging off-road conditions, the HELLA BLADE Series combines powerful illumination with innovative features for the ultimate driving experience, the company said.

Transtar Announces Agreement for Axalta to Acquire The CoverFlexx Group

Axalta Coating Systems has signed a definitive agreement to acquire Transtar Holding Company’s subsidiary The CoverFlexx Group.

Bendix: Air Disc Brake Production has Doubled Since 2018

Commercial ADB adoption rates in Class 6-8 vehicles are now up over 50%, according to Bendix.

MPA: ‘We’re as Strong as Ever’

Chairman, President and CEO Selwyn Joffe discusses what he’d like the aftermarket to know about Motorcar Parts of America.

Dayton Parts Offers New Aftermarket Products

A new DPF differential pressure sensor, engine oil dipsticks and fuel injector wiring harnesses designed to match OEM spec.

Other Posts

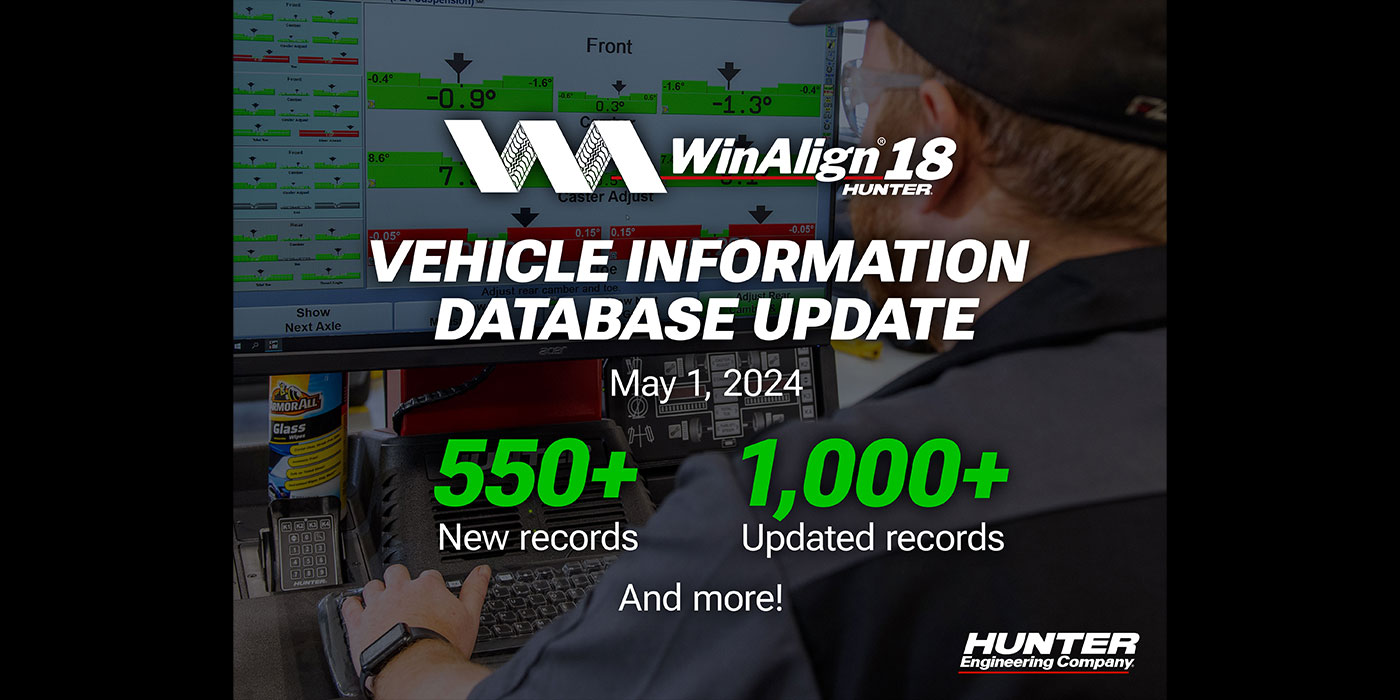

Hunter Engineering Releases Alignment Coverage for Hundreds of Vehicles

The release covers brand-new records – those not yet in existence at the time of the previous release – as well as updates to existing records, covering OEM changes to existing vehicles, the company said.

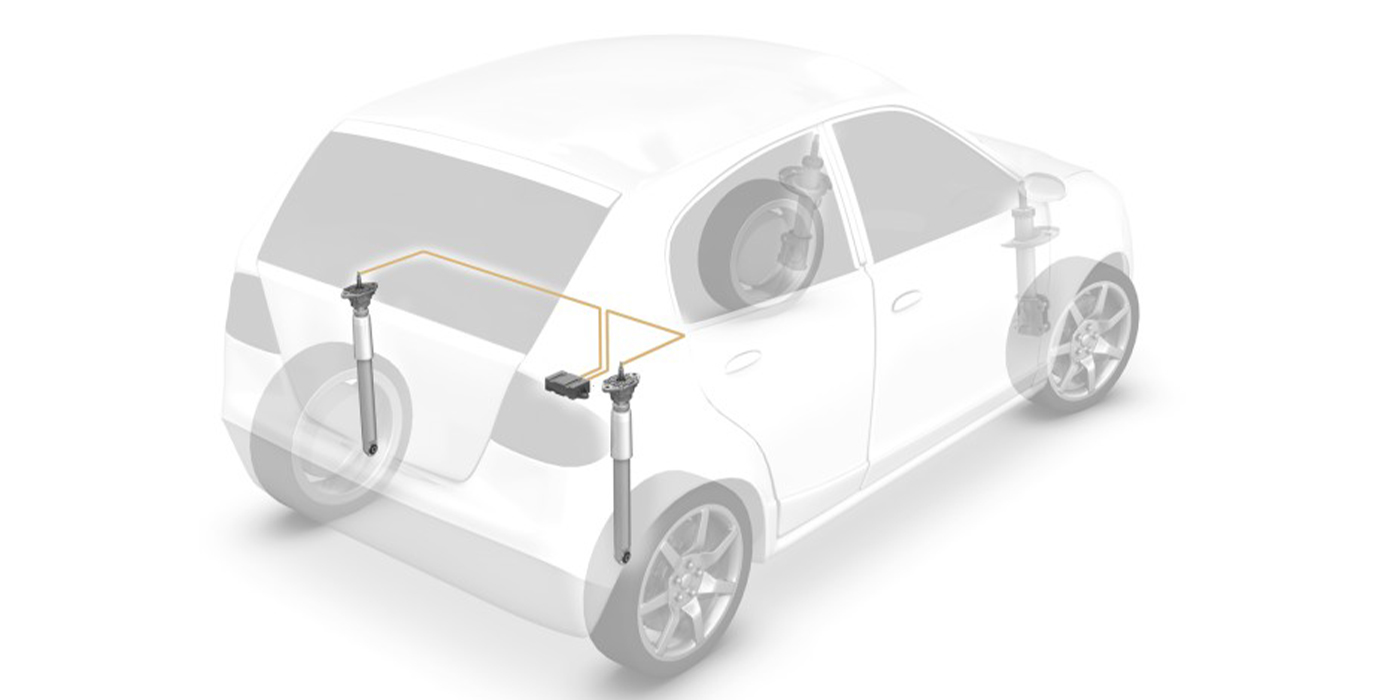

FCS Introduces 42 New Numbers in May

Complete strut assemblies, shock absorbers, shock absorber assembly kits and suspension struts for some of the most popular VIO applications are included in the release, FCS said.

USMW Releases New Fuel Pump Module Assembly

US Motor Works released Part No. USEP9214M, for several BMW applications.

MEYLE Expands Electronics, Sensor Product Portfolio

The focus is on assistance systems and engine and transmission management, with more than 300 new part numbers, as well as the expansion of its product lineup for EVs.