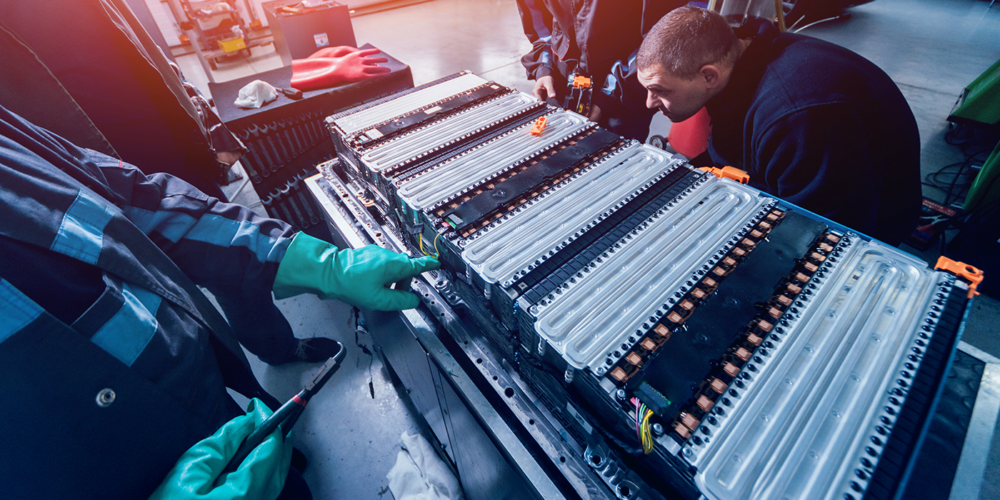

Over the next three to five years, more than 150 new EV models are going to be introduced in the US market. While EVs make up barley a sliver of the car parc now, understanding the parts needed to service these vehicles will be a key component of aftermarket parts manufacturing and remanufacturing in the future. One of those parts is the EV battery.

For OEMS and the aftermarket, EV battery lifecycle management will lead to more efficient usage of the materials that go into making batteries as well as a more sustainable future for the automotive aftermarket. Zo Rahim, senior analyst with Cox Automotive, explained at this year’s MEMA Remanufacturing Conference in October the trends in the EV space and how the increasing need for EV battery service will be benefical for the automotive aftermarket.

The Growth of EVs

According to Rahim, the US is expected to reach about 1 million new EV sales this year, with those numbers increasing over the next decade. With the growth of EVs has come a rise in EV purchase consideration among consumers and ideas around how electric vehicles and technology in the vehicle will make their lives easier.

“Consumers no longer have that same level of range anxiety that they once had,” he says. “They don’t have the same level of concerns around pricing. We are seeing that that’s starting to alleviate as more and more brands and manufacturers start selling into the EV market.”

But as we all know, challenges still exist. Rahim said the US EV market is fragmented. The highest penetration of EV sales are on the West Coast, primarily California. However, all parts of the US are seeing increases year-over-year EV penetration. In addition, US EV adoption rates lag globally. In Europe and China, EV adoption rates spiked quickly.

“The US is trying to play catch up when it comes to EV adoption, sales and EV production, but we do expect the market overall over the next three to five years really to hit some level of critical adoption rates. In our case, over 25% will be considered critical adoption,” Rahim said.

EV Battery Lifecycle Management

For the used vehicle market to mimic the used vehicle market, it takes at least three years. This is important because it represents a lead up time for our industry on how we think about remanufacturing in the EV space, Rahim said. Today, less than a percent of EVs sold are in the used vehicle market, which means the industry should be thinking now about how to address those EV batteries that are coming off the new vehicle market into the used vehicle market. This includes ways to repair them, reman them, extract critical materials and recycle them.

“There’s a lot of excitement around how the industry can think about servicing the new developments that we’re seeing in the EV market,” he said. “There are differences in the batteries. There are differences in the types of materials being used. There are differences in logistics, how you store these batteries. And so, the market currently is trying to figure out the best way to be efficient and the best way to scale these solutions around battery management.”

One critical aspect for the aftermarket to participate in these battery lifecycle solutions is having a detailed right to repair agreement or law, Rahim said. This can determine who repairs EVs and their batteries, as many OEMs currently claim right to ownership of the EV battery data for repair.

“We, of course, know that public and private investments will really drive growth in the EV battery solution space, whether it’s investments in repair facilities, investments in technologies around reman, and even growth in capabilities to move and store some of these batteries overall,” Rahim said.

Brought to you by Motorcar Parts of America (MPA).