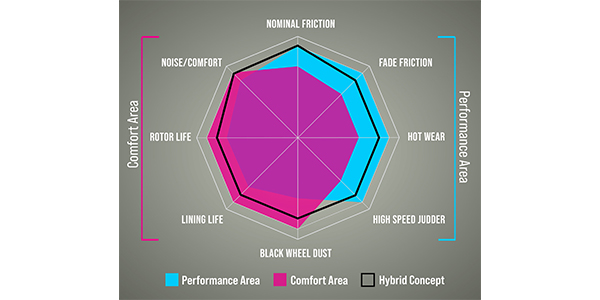

Leveraging its comprehensive material science expertise, Tenneco announced it is introducing advanced OE hybrid friction material composites that simultaneously serve braking performance and comfort requirements in both internal combustion engine (ICE) and electric vehicles (EVs). The new hybrid friction material combines the advantages of low steel (LS) and non-asbestos-organic (NAO) composites in one concept for brake pads.

According to Tenneco, LS materials offer high temperature braking performance and have the unique ability to remove disc corrosion. NAO materials enable good NVH performance and low brake dust contamination. Tenneco’s unique hybrid composite material is expected to cover a range of different market demands with a single approach and is particularly suited to the growing range of electric and electrified vehicles, according to the company.

“I am proud that Tenneco continues its track record of bringing innovative friction materials early to market,” said Neville Rudd, group vice president and general manager, Tenneco Braking. In 2014, our team was one of the first to introduce copper-free braking materials for light vehicles, well ahead of industry regulation. “We see strong potential in our new hybrid friction material composites that enable us to offer outstanding braking solutions for various customer demands, including in the growing e-mobility segment. This expands and diversifies our product portfolio and strengthens our ability to deliver solutions for all our customers, regardless of powertrain strategy.”

Hybrid friction materials: Portfolio diversification in a demanding and changing market environment

While the braking system in traditional powertrains works to provide appropriate deceleration and short stopping distances, battery-electric vehicles, hybrid and plug-in-hybrid vehicles are mainly decelerated by recuperation, largely using the electric motor. When brakes are applied, silent braking performance is key to driver and passenger comfort as there is no engine noise. Reduced use of the brakes can also result in rotor corrosion and rust on the brake discs, which needs to be removed quickly to ensure proper braking performance. Additionally, there has to be sufficient friction power available for emergency braking purposes to ensure short stopping distances to comply with safety requirements.

Holger Schaus, vice president global engineering, Tenneco Braking, added, “We are working closely with OEMs and Tier 1 braking suppliers to match specific requirements and help ensure best-possible performance and comfort with our newly developed advanced hybrid friction materials. While low steel and non-asbestos-organic composites feature different tribology regarding adhesion and abrasion, our comprehensive experience in dedicated material formulations and deep understanding of related science enable us to overcome challenges in this new field and develop advanced solutions that cover a broad range of technical requirements.”

The new hybrid friction material is in series production at Tenneco´s OE Braking facility in Chongqing, China. Several projects are in the testing and evaluation phase in Europe.