Akebono Brake Corp. recently implemented PROLIM, Solid Edge and Teamcenter X software from Siemens Digital Industries to drive the digital transformation of product development, research and design for brake components in North America, where Akebono has been providing braking solutions for domestic and Asian automakers in North America for the past four decades.

“The combination of Solid Edge and Teamcenter X provides us with a powerful, easy-to-use, and agile product development solution, where Teamcenter X will manage our Solid Edge designs and other product-related data. Since it’s a SaaS platform with no infrastructure overhead, we can immediately focus on unlocking opportunities for growth and improved efficiencies through the cloud-based software” says Corey Minter, engineering manager, Akebono Brake Corp. “For years, we have provided the automotive industry in North America with near zero-defect braking system solutions, the PROLIM software will enable us to accelerate our superior diagnosing and problem-solving abilities, shortening the R&D timelines for delivering superior noise, vibration and harshness (NVH) braking products, which is now more important than ever.”

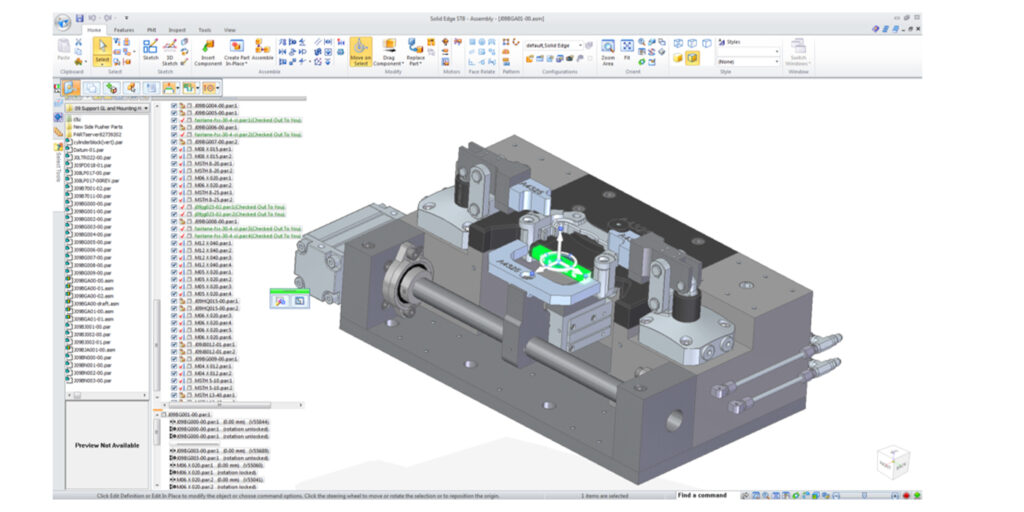

By using the Solid Edge as our 3-D CAD software, Akebono engineers will be able to design equipment and fixtures for caliper manufacturing more efficiently and effectively. The schedules for the development and implementation of new caliper platforms are continuously being reduced; with the changing automobile technology (EPB and Regenerative Braking), time has become a very costly factor. For Akebono to stay competitive in our market, we not only have to adapt to these changes, but we must stay on the leading edge. Using this software enables us to be more fluid and accommodating to our customers’ requests, have more robust designs thus eliminating costly repairs or revisions, and easily share design ideas through the Cloud Based Management System.

Teamcenter X, a cloud-based Product Lifecycle Management (PLM)-as-a-service innovation platform, brings the power of the cloud to all users, helping to reduce time-to-market and connect distributed, cross-disciplinary teams while improving effectiveness and efficiency at any scale.

“Solid Edge is a complete portfolio of product development tools, including mechanical design, simulation, manufacturing and technical publications. Combining that with the instant-on PLM value of Teamcenter X, we offer a comprehensive solution with a very fast return on investment,” said John Miller, senior vice president for Mainstream Engineering Software, Siemens Digital Industries Software. “Our partnership with PROLIM enables us to help innovative companies like Akebono achieve their digital transformation goals faster.”

Teamcenter X, a cloud-based Product Lifecycle Management (PLM)-as-a-service innovation platform, brings the power of the cloud to all users, to help reduce time-to-market and connect distributed, cross-disciplinary teams while improving effectiveness and efficiency at any scale.

“Combining traditional PLM with cloud computing allows PLM to be available anywhere and, on any device, reduce IT resource needs, and keep up with the latest innovative technology, while enabling enterprises to move the investment from a capital expenditure to an operational expenditure,” says Prabhu Patil, founder and CEO of PROLIM.