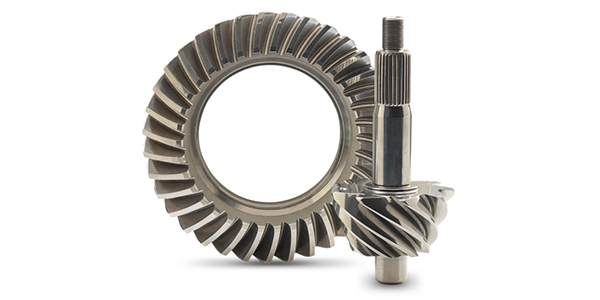

Eaton recently introduced its QuietTec technology ring and pinion gear sets at the SEMA Show in Las Vegas. The QuietTec gear sets are specially designed for high-performance automobiles where a smooth, quiet gear setup is typically difficult to achieve.

Ring and pinion gears are key components of a vehicle’s driveline that transmit engine power from the driveshaft to the differential, which then powers the axles of the vehicle to rotate the wheels.

QuietTec gears are manufactured with gear-cutting technology to maximize tooth contact while reducing tooth-to-tooth contact pressure, delivering improved strength, durability and heat reduction. With an extremely consistent tooth mesh-and-gear contact pattern, QuietTec gears make it easier to achieve proper mesh, which reduces installation time, said the company.

“QuietTec ring and pinion sets are manufactured with extreme precision using the latest cutting technology to provide optimized performance and reduced noise, vibration and harshness in the vehicle and driveline,” said Tim Bauer, vice president, Aftermarket, Eaton’s Vehicle Group North America. “These new ring and pinion sets from Eaton are for the high-performance enthusiast. Whether cruising down the street or competing on the track, these sets pair nicely with Eaton’s broad portfolio of performance differentials.”

QuietTec gear sets are currently available for Dana 60, Ford 8.8″ and Ford 9″ axles.