Kinedyne LLC, a designer, manufacturer and distributor of cargo control technologies, including cargo securement, capacity and access solutions for the transportation industry, announced that its new distribution facility is fully operational.

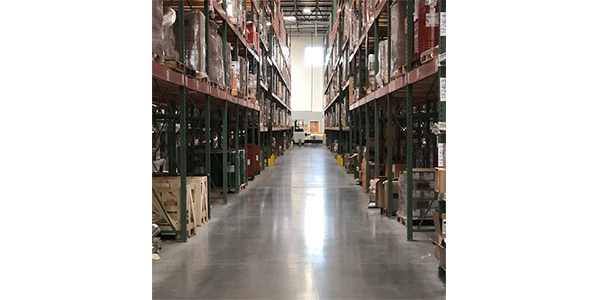

This new distribution facility is the most recent expansion of the company’s Prattville, Alabama, operation. Kinedyne began consolidating engineering, manufacturing, quality control, supply chain management, customer service and government contract functions within its 200,000-square-foot facility in late 2016, to improve overall speed, efficiency and productivity.

Equipped with the latest inventory management technology, the capabilities of the new distribution, logistics and warehouse operation will significantly improve Kinedyne’s order processing, lead time and accuracy, said the company.

“With over 20 years of experience in operational strategy and global manufacturing, Doug Apelt, vice president – operations, oversees all operational processes in the United States and Canada,” said Dan Schlotterbeck, president of Kinedyne LLC. “Doug’s operational expertise and leadership of the Prattville team has benefitted this expansion initiative and continues to strengthen and improve the efficiency and effectiveness of our overall North American operations.”

“This is an exciting opportunity for us to further improve operational integrity through process control and technological advancements,” said Apelt. “Employees and customers will each enjoy the advantages generated by the additional facility, and it positions Kinedyne to successfully manage its customers’ expectations and our own future growth objectives.”

Kinedyne has called Prattville home for several decades. With this expansion and nearly 300 employees, it remains among Autauga County’s largest employers. Kinedyne’s distribution facility now supports the distribution of the many products made in its Prattville manufacturing operation, including government/military products, cargo nets, helicopter slings, tow straps, logistics straps and the company’s renowned load securement straps.