Velodyne LiDAR has announced a significant cost reduction for its most popular LiDAR sensor, the VLP-16 Puck, with the aim to spur hope and excitement for the development of safe autonomous vehicles that are accessible to all. The VLP-16 is now offered to customers around the world for up to a 50 percent cost reduction.

Velodyne LiDAR has announced a significant cost reduction for its most popular LiDAR sensor, the VLP-16 Puck, with the aim to spur hope and excitement for the development of safe autonomous vehicles that are accessible to all. The VLP-16 is now offered to customers around the world for up to a 50 percent cost reduction.

“Demand for our VLP-16s grew tremendously in 2017. As a result, we increased capacity and now can pass along savings as cost reduction to our customers,” said David Hall, founder and CEO, Velodyne LiDAR. “We want to make 2018 a year of optimism for the autonomous vehicle, especially as the first waves of robocabs hit the road. Our goal is the democratization of transportation safety by making it accessible to every man, woman and child in the world as quickly as possible.”

Velodyne’s sensors are rolling off the assembly line as a result of large-scale automated manufacturing at its San Jose Megafactory. Established earlier this year, the megafactory today leverages advanced and streamlined manufacturing techniques to build a range of Velodyne LiDAR sensors, including the Ultra Puck VLP-32C and the recently announced VLS-128. The megafactory employs hundreds of people who fulfill engineering, manufacturing and corporate functions for Velodyne, which has more than doubled its full-time employees over the past six months. As noted by Hall, the megafactory has established a business case for U.S.-based production, because even as automation has increased, so has hiring as the company invests heavily in automation and the skilled support staff that it requires.

“Since its launch, customers have been lining up to purchase the VLP-16 and we’ve been able to meet that growing demand by expanding production and developing automated manufacturing for LiDAR sensors at the Megafactory,” said Hall. “With this cost reduction, we’ll be able to get more Pucks into the hands of more customers, support the growing number of autonomous vehicle development fleets around the world, and start creating a better tomorrow.”

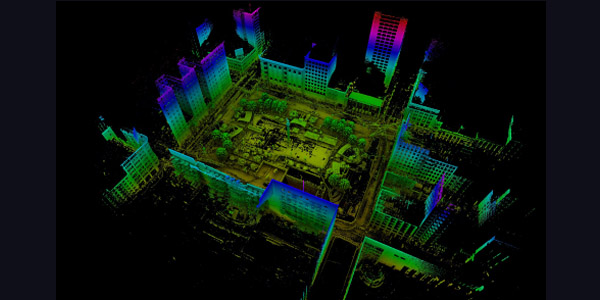

The VLP-16 was launched in 2016 and had an immediate impact on multiple industries, most notably automotive. It delivers a small, accurate, reliable and affordable sensor for real-time 3-D vision with 100 meters of range and a 360-degree surround field of view. Today, the VLP-16 is one of the most widely adopted LiDAR sensors ever made, according to Velodyne, with use cases that span a multitude of industries, including automotive, freight, 3-D mapping, unmanned aerial vehicles, industrial and robotics.

“The VLP-16 opened the door for advanced LiDAR technology in several industries that benefit from real-time 3-D data in a small form factor,” said Mike Jellen, president, Velodyne LiDAR. “As interest in LiDAR technology grows around the world, we’re gratified to know that the Puck will be one of the most widely used and accessible sensors available.”

Velodyne LiDAR invented and patented the world’s first 3-D real-time LiDAR sensor for autonomous vehicles. Over the past 10 years, Velodyne sensors have been installed in thousands of vehicles around the world, traveling millions of real-world miles. Velodyne provides technology for dozens of autonomous vehicle programs in more than 10 countries.