MADISON, IN — Grote Industries Product Development Engineer, Edward Sitarski, has been presented with the Employee Involvement Association’s Individual IDEA of the Year Award for 2007. For more than 65 years, the Employee Involvement Association has provided quality educational programs to a broad range of industries who understand that their employees have the ideas to help make their companies more productive and profitable. EIA’s Annual Awards Program, the highlight of its annual international conference, focuses on outstanding ideas of the year and leadership of employee involvement and suggestion systems programs. Approximately 250,000 ideas are submitted each year from companies globally.

At right: Sitarski (left) accepts his award.

Sitarski’s idea to automate manual terminal connector LED production bested 90 finalists for the win.

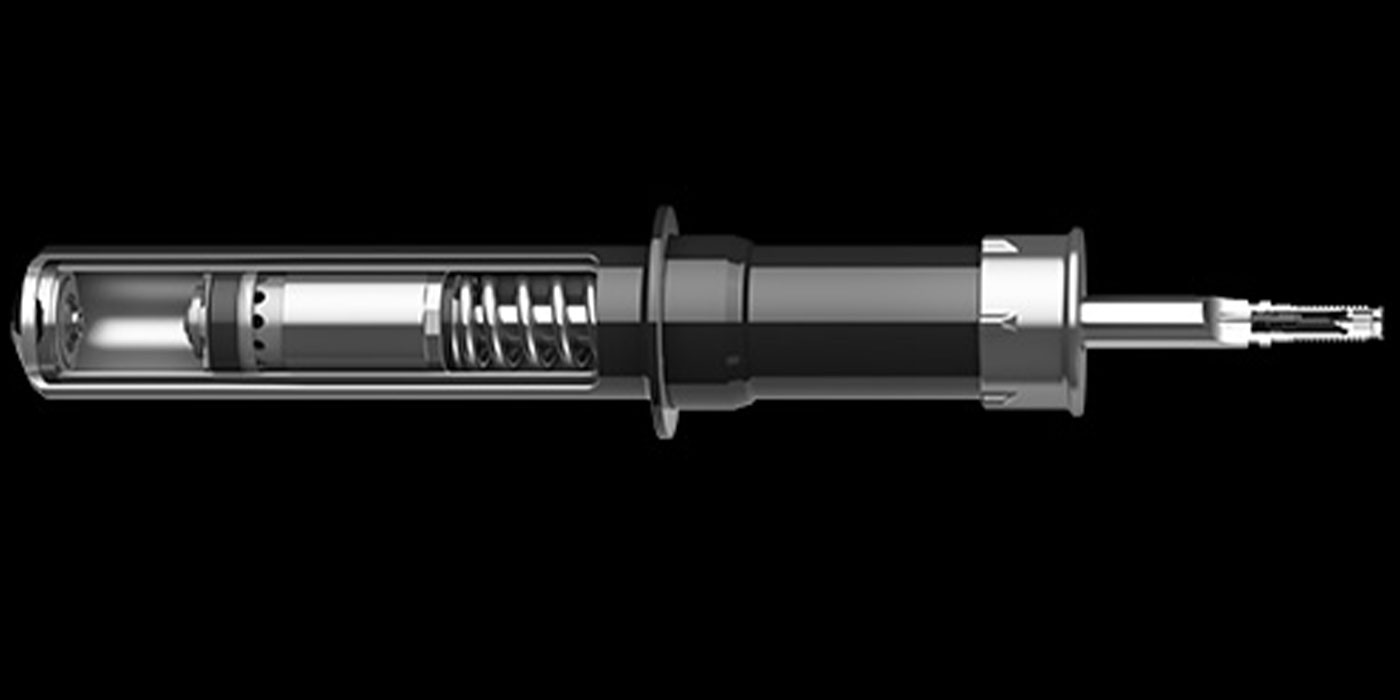

The EIA Idea of the Year Award is based on finding an innovative solution for an existing problem. Grote’s challenge was to lower the cost on its’ LED head and tail lamps, dome lights, emergency lighting and marker lamps, thus allowing Grote to provide customers with more economical LED lighting solutions. This had spurred Grote Industries to rethink its manufacturing workflow. Challenge turned into opportunity when Sitarski proposed robotics for improving manufacturing performance and productivity.

"Not only did the company decrease its cycle time by over a third, but it also realized dramatic savings annually with this new technology," said Sitarski.

The EIA said it was impressed with numerous features of the robot cells: non-contact soldering methods, vision system robot orientation, plug-n-play hardware interchange, advanced process monitoring, product testing and quick-change capabilities. Those capabilities allowed Grote to manufacture a multitude of different inventory part numbers at these stations, with changeover taking less than five minutes. Most importantly, the EIA was surprised with the numerous manufacturing challenges and innovative processing technology associated with the automated cells. The technology was so innovative the project was partially funded from a State of Indiana Grant under the Advanced Energy Technologies Program.

Using robotics gained the company efficiency, flexibility and improved quality control. With flexibility came the need to find a potting material that met Grote’s stringent engineering requirements and the high production rate demands of the automated equipment. After 15 months of development, Grote found its answer with a specially formulated potting. The material’s fast flow and cure rate makes Grote’s LED lamps more durable, and in most cases, moisture and corrosion resistant.

With the successful application of robotics, new process technology and specially formulated potting material, Grote has been able to produce its enhanced, LED lamp assemblies under the SuperNova and LED WhiteLight trademarks. "A significant tangible benefit to our customer is the improved part aesthetics, numerous product enhancements, and better quality," said Dominic Grote, vice president of sales and marketing for Grote Industries.

The benefits of robotic LED production have greatly improved employee safety as well. No longer is the operator in close proximity to solder fumes, solder spatter, potting fumes or the curing source. Potential for carpal tunnel injury from repetitive small part manipulation is also greatly reduced.

The pairing of robot teams has improved manufacturing and workforce performance, as well as equipment and operator utilization, allowing Grote to reallocate human resources to other shifts or work areas. Overall improvements in production line efficiencies such as this, throughout the facility, has lowered product cost, increased utilization and improved Grote’s competitive standing in the global marketplace, the company said.

For more information about Grote, visit: www.grote.com.