Cummins Inc. announced that the company has received two awards from the U.S. DOE’s (DOE) Office of Energy Efficiency and Renewable Energy (EERE) totaling nearly $7 million. The awards are for Cummins’ continued work on enhancing economic viability of fuel cell powertrain solutions for heavy-duty applications including on-highway tractor-trailers and buses.

Cummins is the project lead and is working with a number of public and private partners on these projects, which are part of DOE’s “H2@Scale” initiative to develop affordable hydrogen production, storage, distribution and use.

Cummins is a global leader in fuel cell applications with more than 2,000 fuel cells and 600 electrolyzers already put into use and is making continued efforts to deepen its capabilities and bring more hydrogen and fuel cell power solutions to markets.

“Programs like ‘H2@Scale’ are essential to gain the scale and investment needed that will lead to faster adoption of hydrogen fuel cell technologies,” said Amy Davis, President New Power, Cummins Inc. “The work we are doing with the DOE and our partners will help improve cost and operational performance of hydrogen fuel cell technologies to achieve greater parity with other available power solutions. We are looking forward to moving this technology forward and bringing additional hydrogen products to our customers.”

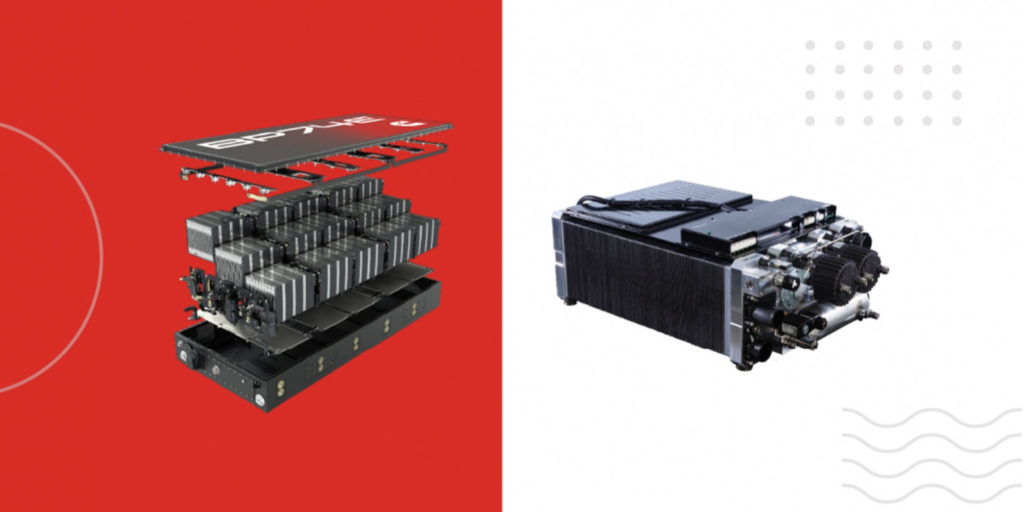

The first award for approximately $3.5 million is for the development of an integrated fuel cell electric powertrain for heavy-duty trucks and transit buses with operational performance and total cost of ownership that supports near-term, rapid, and substantial penetration of the truck and bus market. This includes development of a solution that is highly manufacturable and scalable with a proven range of 300 miles or more and improved fuel economy over current heavy-duty trucks and transit buses. Other objectives include achieving, meeting or exceeding conventional diesel powertrain performance requirements and reducing the upfront capital costs by 35% to make the adoption of zero-emission fuel cell technologies viable for commercial fleets.

The second award for $3 million is to develop and validate a high pressure, modular, 100 kW proton exchange membrane (PEM) fuel cell stack and system to power heavy-duty applications. The objective is to optimize the fuel cell stack for efficiency, power density, space and cost for operation at or above 100°C that can achieve a minimum operating time of 25,000 hours and achieve $80/kW in volume production, which is necessary to make the stacks economically viable in the U.S. The fuel cell stack components will be developed and prototyped in the U.S. to encourage continued investment in this technology and increase scalability.

Cummins’ New Power segment, which combines the company’s investments in electrified powertrains, fuel cells and hydrogen production technology, completed its first full year in 2019.

The group successfully brought zero emissions electrified powertrains to bus markets in North America in 2019. Cummins also has more than 2,000 fuel cell installations across a variety of on and off-highway applications, as well as more than 600 electrolyzer installations to split water into hydrogen and oxygen.

The company says these technologies will play a prominent role in the company’s PLANET 2050 aspiration to ultimately power customer success through carbon-neutral technologies.