AMN Perspectives by Thomas Group: Experience at Work

Posted: Aug. 24, 2004, 9 a.m., EST

by John Steidl, Thomas Group consultant and David Demers, president of Avicon.

IRVING, TX — In our previous article, we outlined five key challenges facing today’s supply chain architects. Starting this week, we want to present a dramatic new approach to supply chain engineering that responds to these challenges. The challenges were:

1. The trend toward outsourcing;

2. Wall Street expectations for accelerated cash velocity;

3. New business models introduced by companies like Dell, Wal-Mart and Zara;

4. Unplanned global events; and

5. Shorter product life cycles in virtually all industries.

A handful of industry leaders are beginning to adopt a new approach through a supply chain model called the “integrated operating system.” Unlike older models, this new model is capable of helping companies outperform weaker competitors by simultaneously reducing working-capital requirements, improving revenue and margin contributions and improving order-to-delivery predictability and response time. The new model is particularly well suited to companies that are experiencing product commoditization pressures.

Each integrated operating system has its own unique footprint, which we call supply chain DNA. Unlike human DNA, supply chain DNA can be adaptively configured to deliver the desired business values. DNA are distinctive strategy and capability building blocks that drive supply chain innovation. In the integrated operating system model, the DNA are grouped into solution patterns spanning four essential business areas: process, information, cash and organization (PICO).

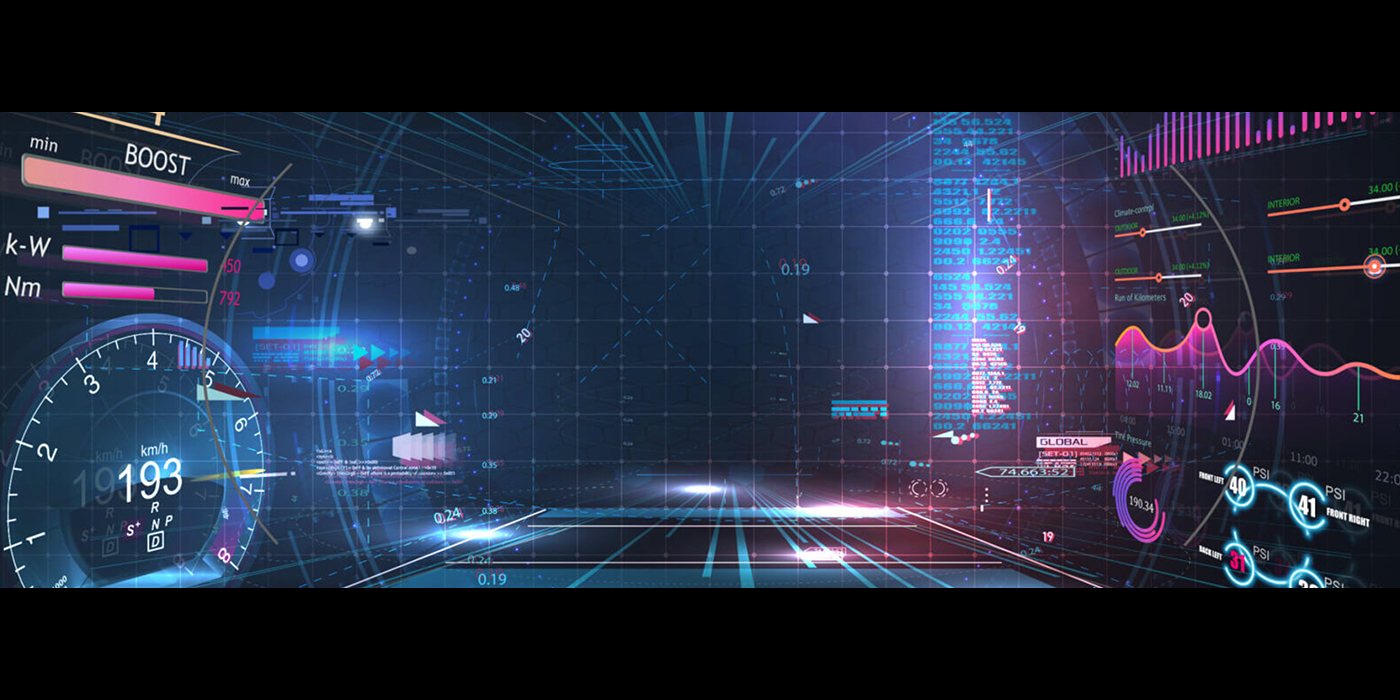

Leading companies have developed integrated operating systems by selecting a unique blend of DNA and configuring these into DNA solution patterns organized in the four PICO areas to best suit their strategic needs. The resulting supply chain integrated operating system drives the simultaneous achievement of improved customer response, higher revenue and margin contributions, and faster cash-to-cash velocity. This innovative supply chain lifecycle is illustrated in Exhibit 1.

The Integrated Operating System Model

Two strategic shifts are spearheading the migration to an integrated operating system. The first shift involves the broad recognition that supply chain velocity is fundamental to performance, efficiency and competitive differentiation. Technology companies like Apple, Cisco, Dell and others that have mastered the concept to gain a competitive advantage over their rivals have highlighted the advantages of high-speed supply chain strategies. These companies didn’t have an influx of cash or the prowess of vast research-and-development budgets, so they chose to compete on business innovation instead of product innovation. In a recent issue of MIT Sloan Management Review, Paul Kampas discussed the significance and implications of strategic shifts like this one. Underlying the business-innovation strategy is a relentless pursuit of an improved business operating model. Today, the application of streamlined supply chain strategies is spanning electronics, retail, automotive and other market sectors where product-innovation strategies are no longer enough to win market share.

The second strategic shift is the application of systems thinking to the transformation of supply chain models. In our view, the leaders are taking a more holistic view of the supply chain in designing their models. They are now engineering their models with four critical dimensions of PICO in mind. These dimensions form the four support components of the integrated operating system, which require concurrent engineering to attain peak performance. In upcoming installments we’ll talk more about design and implementation in the key dimensions of PICO.

_______________________________________

Click here to view the rest of today’s headlines.