AMN Perspectives by Thomas Group: Experience at Work

Posted: Oct. 27, 2004, 9 a.m., EST

by John Steidl, Thomas Group consultant and David Demers, president of Avicon

IRVING, TX — NMS Communications, a mid-sized network equipment manufacturer, employed the Thomas Group DNA building-block approach to reengineer the supply chain for its platform business, which accounts for 80 percent of the company’s revenue. NMS realized that to maintain a competitive edge, it needed to create a high-speed, demand-driven supply chain. But developing such a capability in an environment where forecasts traditionally ruled was a challenge. NMS attacked the problem using a three-phased approach:

1. Assess the supply chain baseline data and define a vision using the new DNA building blocks organized in the process, information, cash and organization (PICO) quadrants.

2. Design new business processes, information systems, working-capital optimization tools and rapid cash cycle conversion methods. Align the organization to the desired outcomes.

3. Execute time-phased implementation and adaptive deployment of the PICO changes.

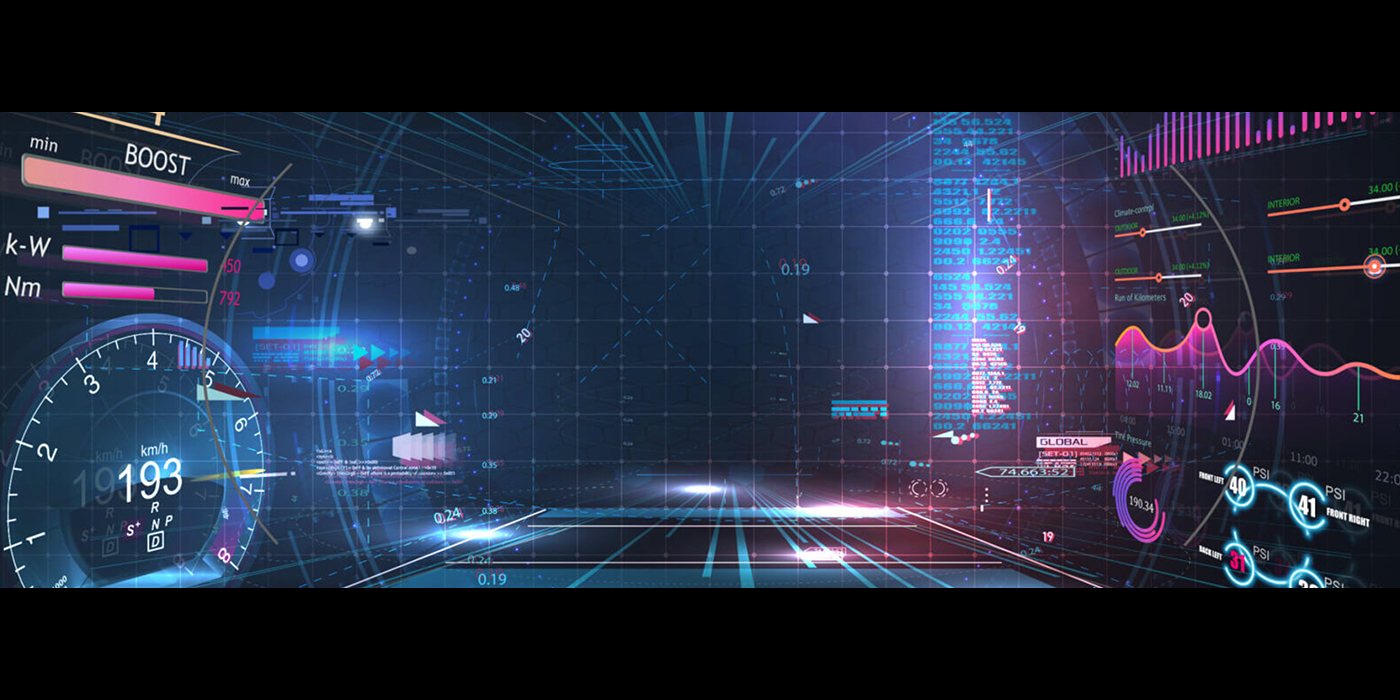

This was not a one-time project, but rather a multiphase, disciplined process that began 18 months ago using the DNA-based life-cycle model. In order to establish the initial demand-driven foundation, NMS conducted a preliminary assessment of its supply chain and identified the key outcome metrics. This assessment helped the company define the vision of the desired high-speed model and identify the DNA building blocks necessary to support this vision. (The DNA building blocks deployed for converting NMS to a high-speed integrated operating system are show in Exhibit 7.) The building blocks defined the company’s unique demand-driven pattern, which had to be deployed quickly and sequentially.

Throughout this process, NMS realized that converting to a high-speed model required multiple changes. Product design, for example, had to be changed to support manufacturing. Designs had to be created with more standard parts for fewer saleable items. In addition, because NMS had outsourced manufacturing capabilities, it needed to work with its contract manufacturer to reduce manufacturing setup time, implement vendor-managed inventory (VMI) capabilities with suppliers, and develop new contracts to manage risks based on upside and downside demand flexibility. The company recognized that the new model would be heavily dependent on information systems capabilities. For this reason, it deployed supply chain planning systems to enable the high-speed operation. Near real-time integration was established internally, connecting the disparate internal systems, and externally with the contract manufacturer. NMS partners were given access to the internal systems via an extranet.

Over subsequent phases, NMS rationalized its supplier base and established a more strategic relationship with its contract manufacturer, employing collaborative procurement programs and an open-book relationship. Cash-engineering projects were initiated to facilitate faster cash-conversion cycles for the company and for the partners by improving outstanding sales and payables. NMS also instituted customer/vendor scorecards and internal balanced scorecards to continuously measure and yield improvements. In the organization area, the company initiated programs to change the company’s culture to be driven by innovation, pervasive leadership values and a flexible workforce motivated by integrated rewards and incentives.

The competency and attitude of both the people within NMS Communications and its partner companies played a key role in the successful transformation effort. Key outcomes of that effort to date include:

* 52 percent reduction in inventory levels;

* 45 percent faster order fulfillment times;

* 300 percent faster manufacturing times;

* 96-97 percent of delivery commitments made; and

12 percent reduction in supply chain costs.

For additional information, visit www.thomasgroup.com .

_______________________________________

Click here to view the rest of today’s headlines.

“AMN Perspectives by Thomas Group: Experience at Work” is written and sponsored by Thomas Group. The opinions expressed in “AMN Perspectives by Thomas Group: Experience at Work” articles appearing on aftermarketNews.com do not necessarily reflect the opinions of AMN or Babcox Publications.