Bridgestone Americas (Bridgestone) broke ground this week on a $51 million expansion of its Firestone Industrial Products’ (FSIP) air springs production facility in Williamsburg, Kentucky. The 68,000-square-foot expansion of the Williamsburg Plant is aimed at meeting growing demand for the company’s air springs products, driven by the burgeoning electric vehicle (EV) sector. The expansion, expected to be completed by December 2022, will add 250 new jobs, a nearly 50 percent increase from the more than 500 employees working today at the facility.

“Today, we celebrate the vitality and growth of this plant and this community, with new investment, new jobs and a physical expansion driven by growing demand for our products and, just as fundamentally, by this team’s commitment to delivering innovation and superior quality for our customers here and around the world,” said Emily Poladian, president, Firestone Industrial Products. “Our company and our Kentucky team have a vital role to play in the transformation of mobility brought forth by advanced electric vehicle systems and by key supporting technologies like our Firestone air springs and air suspensions.”

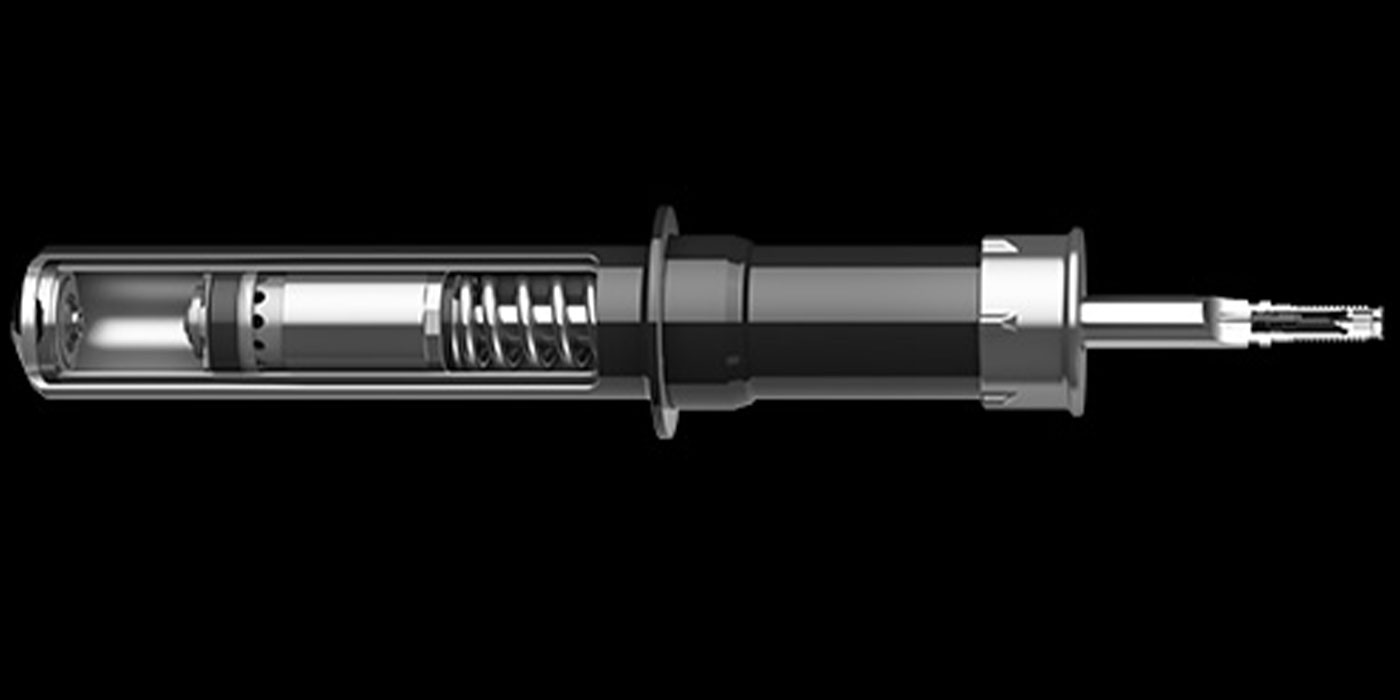

FSIP is a leading global supplier of air suspensions for the EV industry. Firestone air suspensions not only help improve ride comfort and handling, but also can increase electric vehicle range and help protect batteries from road impact and overheating. This new chapter was born from a decades’ long history of designing and supplying parts to the majority of commercial vehicle manufacturers in North America. During the COVID-19 pandemic, the company has supplied product to keep these essential services providers moving. Its products include Ride-Rite, Airide, Airide Pro, Airogear and Marsh Mellow air springs.

FSIP designs, tests and manufactures components for air suspensions in Williamsburg, Kentucky, which is the only full U.S. manufacturer of this product category. FSIP operates a second plant, in Dyersburg, Tennessee, where air springs are assembled. FSIP’s North America Advanced Technical Design Center, in Fishers, Indiana, enables the company to remain agile and focus on speed to market, a key requirement of start-up EV companies. The company also operates plants in Brazil, China, Costa Rica and Poland.

FSIP purchased the building and land located in Williamsburg in 1988. The Williamsburg Plant is currently 375,000 square feet. It is one of the largest employers in the area with more than 500 employees. Williamsburg Plant employees embody the company’s global corporate social responsibility commitment, Our Way to Serve, with initiatives in community support, education and environmental conservation and preservation.