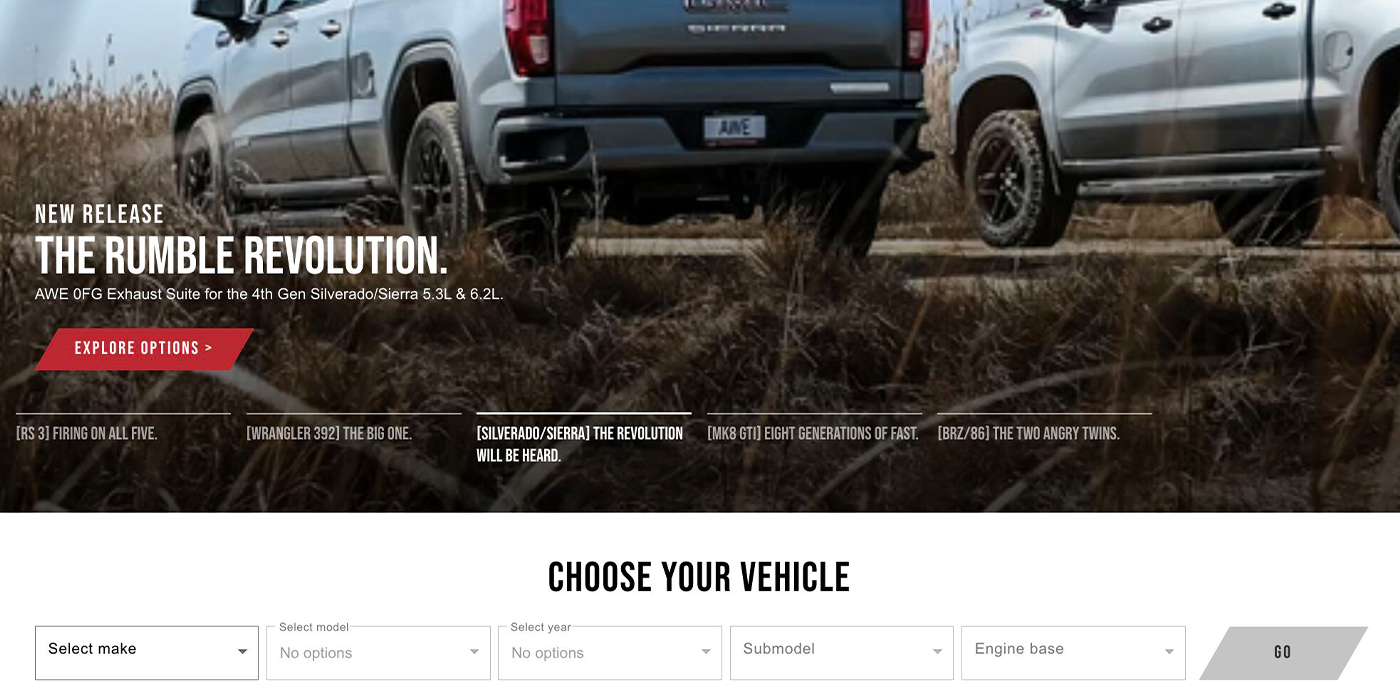

AWE has launched a company-wide manufacturing efficiency program that has streamlined the production of AWE’s exhaust products, enabling them to be produced in a manner that decreases customer lead time on certain items and increases the company’s ability to produce higher volumes of products given higher demand over the trailing 12 months.

AWE has launched a company-wide manufacturing efficiency program that has streamlined the production of AWE’s exhaust products, enabling them to be produced in a manner that decreases customer lead time on certain items and increases the company’s ability to produce higher volumes of products given higher demand over the trailing 12 months.

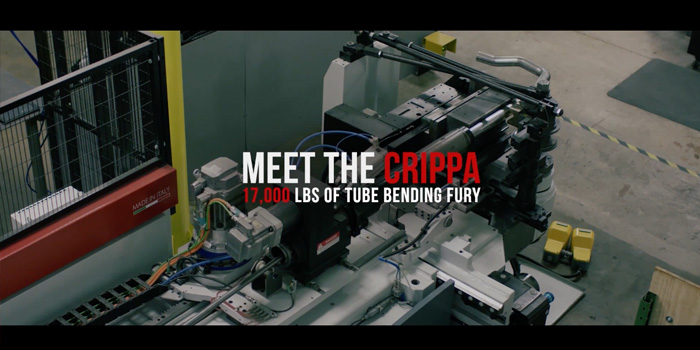

“AWE has updated new processes and procedures, and brought in equipment, including but not limited to our CNC mandrel bender from Crippa, our robotic cutting equipment from ABB, laser etching by Laser Marking Technologies, all in-house, so that our A-team can become even more streamlined while keeping quality up and performance of the products above standards,” said Jason Hertz, production manager.

The company also has implemented a new company-wide dash-boarding system to monitor throughput for “all to see” in order to foster a company culture of increased throughput, from order to ship.

“Production floor streamlining, coupled with volume amplification through leading sales and marketing, was always part of the long-term strategy,” said Todd Sager, president and founder of AWE. “The European vehicle market continues to grow for AWE, and our Ford Mustang, Ford Focus and Subaru lines have exceeded expectations to the point where their volume can support dedicated manufacturing cells. A focus on both quality and efficiency is essential to AWE’s DNA.”