Atlas Copco’s next-generation air filters now feature the pioneering inPASS technology to simplify maintenance and reduce costs significantly. The new range also gives customers the flexibility to choose between advanced filter media to match their specific air quality requirements.

Filtration is a crucial but sometimes overlooked component of a compressed air system. There is an assumption that all filters do the same job and have the same filtration properties. However, untreated or poorly treated compressed air can contain dirt, water, and oil, compromising tools, production processes, and final products. That is why Atlas Copco offers a complete range of filters that remove even the smallest contaminants — from dust to water and oil vapors.

As part of its continuous investment in filtration R&D, Atlas Copco is now introducing a host of pioneering new technologies to its UD+, DD+/PD+, DDp+/PDp+, and QD+ filter range. The new features have a significant impact on customers’ air quality and operational costs.

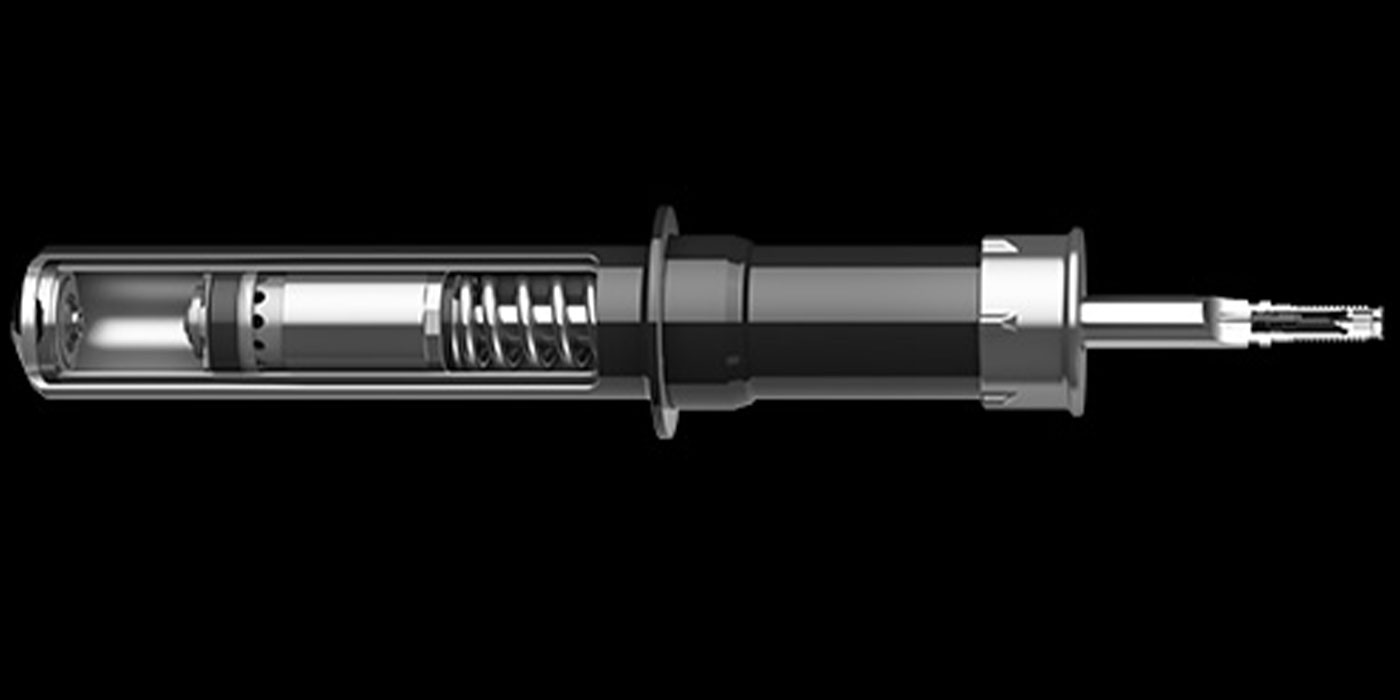

The most eye-catching innovation is the inPASS bypass. Until now, servicing a filter involved shutting down the entire compressed air system or installing three-valve bypasses around every filter. The inPASS re-directs the air through the filter head during maintenance, allowing for safe filter cartridge replacement without interruption of the airflow. This means there is no need to install extra piping around the filters or halt production maintenance. As a result, the inPASS saves customers on both installation and operational costs by allowing quick, seamless service.

Atlas Copco has developed specialized filtration methods and media to take on specific contaminants to maximize air quality. This includes a wrapped filter element for wet particles, a pleated element for solid particles, and macro-structured activated carbon for oil vapors. Centrifugal filters also are available to remove water droplets from the airflow. As a result, customers enjoy the flexibility to choose the best filtration technology for their production environment.

Atlas Copco’s new filters also come with a user-friendly service indicator that displays running hours, differential pressure and maintenance status. This allows users to maximize the lifespan of their filters and to plan the best time for maintenance. There is also a malfunction alert on the filter head connected to a remote monitoring device.

Jan Norz, product marketing manager for air treatment equipment with the Atlas Copco Industrial Air division, said, “Filters are more than a mandatory add-on to an air system. Filtration technology directly affects the reliability, lifetime, and cost-efficiency of an entire production system. That is why we have a dedicated filtration R&D team and in-house testing facilities. They allow us to develop breakthrough technologies like the inPASS, innovations that help safeguard our customers’ production quality and reduce their costs.”

The new Atlas Copco UD+, DD+/PD+, DDp+/PDp+, and QD+ filter range is available worldwide now.