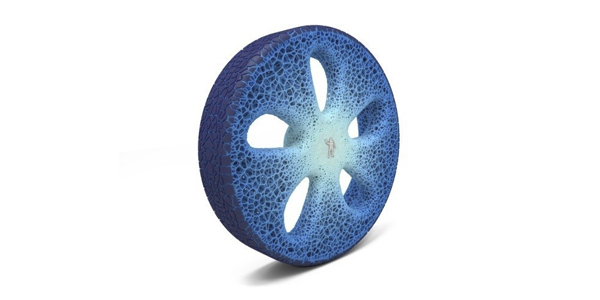

At Movin’On 2018, Michelin is announcing its plan to ensure that, by 2048, all of its tires will be manufactured using 80 percent sustainable materials and 100 percent of all tires will be recycled.

At Movin’On 2018, Michelin is announcing its plan to ensure that, by 2048, all of its tires will be manufactured using 80 percent sustainable materials and 100 percent of all tires will be recycled.

Today, the worldwide recovery rate for tires is 70 percent and the recycling rate is 50 percent. Michelin tires are currently made using 28 percent sustainable materials (26 percent bio-sourced materials like natural rubber, sunflower oil, limonene etc., and 2 percent recycled materials such as steel or recycled powdered tires). For a sustainable future, Michelin is investing in high-technology recycling technologies to be able to increase this content to 80 percent sustainable materials.

Sustainable Materials

The route to this ambitious sustainable material target will be achieved by research programs into bio-sourced materials like Biobutterfly and working with Michelin’s high-level partners, and the advanced technologies and materials that are being developed in these partnerships. The Biobutterfly program was launched in 2012 with Axens and IFP Energies Nouvelles to create synthetic elastomers from biomass such as wood, straw or beet.

Michelin is developing innovative solutions today in order to integrate more and more recycled and renewable materials in its tires, while continuing to improve performance, including 30 percent of recycled materials by 2048. The company says this is demonstrated by the recent acquisition of Lehigh, a specialist in high-technology micro powders that are derived from recycled tires.

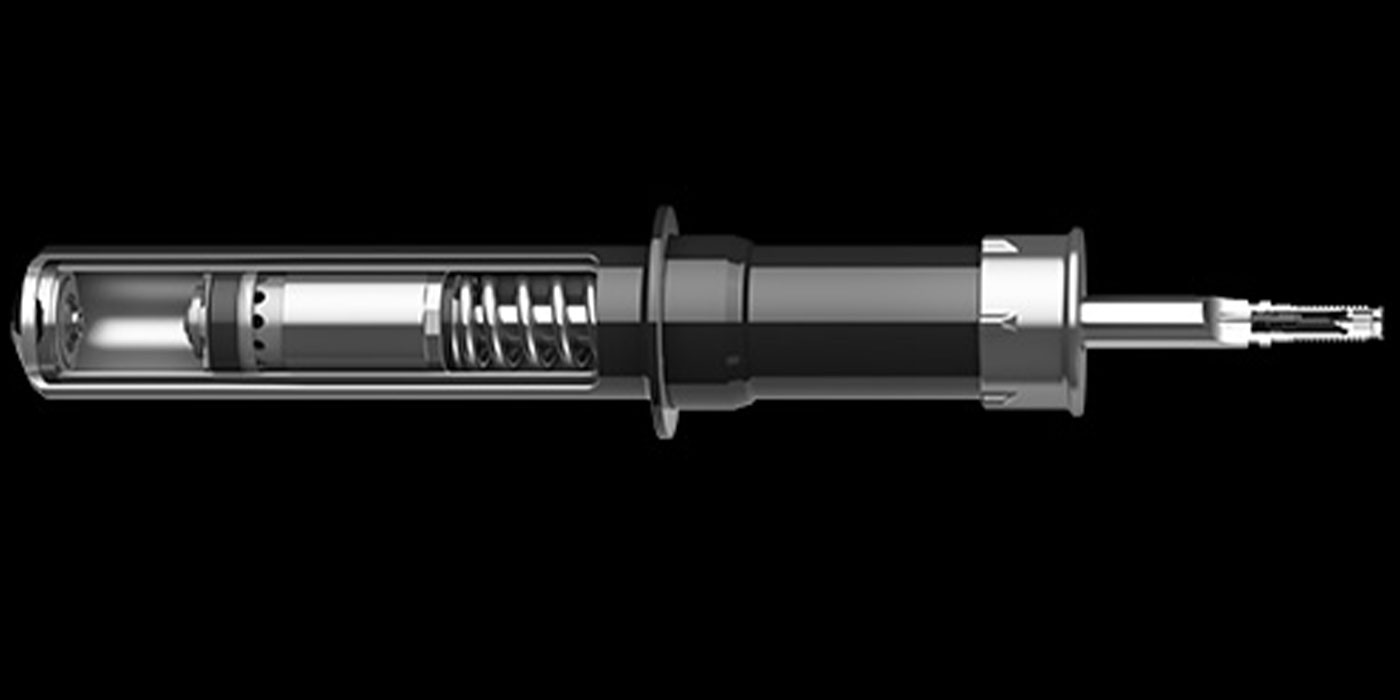

Lehigh Technologies is a specialty chemical company that is part of the High Technology Materials Business Unit of Michelin. Lehigh is the leader in the marketplace for micronized rubber powders (MRP), a sustainable raw material that reduces feedstock costs by up to 50 percent and delivers performance without compromise across a wide range of markets.

MRP replaces oil- and rubber-based feedstocks in a wide range of industrial and consumer applications, including high-performance tires, plastics, consumer goods, coatings, sealants, construction materials and asphalt. Lehigh technical experts collaborate with customers to optimize products for each application.

Lehigh operates the world’s largest MRP manufacturing plant in Tucker, Georgia, with an annual production capacity of 54,000 tons. Lehigh’s state-of-the-art Application and Development Center also is located in Tucker and serves as an innovation hub where Michelin conducts research and formulates MRPs in collaboration with its customers. Michelin has five product ranges so far, PolyDyne, MicroDyne, EkoDyne, Rheopave and Zenoflex, and continues to expand the range of solutions in core markets. Lehigh Spain, a joint venture with Hera Holding, is based in Barcelona. The first Lehigh plant outside of the U.S. – located in Murrillo del Fruto – is under construction and will begin operations this summer.

Commenting on this venture, Christophe Rahier, director of the high technology materials business line at Michelin, said, “This acquisition demonstrates Michelin’s strategic determination to capitalize on its expertise in high-tech materials, in areas that extend beyond the field of tires. In particular, by promoting the use of innovative recycled materials from tires in a variety of non-pneumatic industrial sectors.”