Hyundai Motor Co. has completed South Korea’s first domestic highway journey with an autonomously navigated semi-trailer truck. Hyundai’s Xcient truck drove approximately 40 km (24.8 miles) on the highway between Uiwang and Incheon, carrying a large semi-trailer simulating cargo transportation, showcasing Hyundai’s innovative technological advancement in future mobility.

Hyundai Motor Co. has completed South Korea’s first domestic highway journey with an autonomously navigated semi-trailer truck. Hyundai’s Xcient truck drove approximately 40 km (24.8 miles) on the highway between Uiwang and Incheon, carrying a large semi-trailer simulating cargo transportation, showcasing Hyundai’s innovative technological advancement in future mobility.

Hyundai says it continuously invests in cutting-edge infrastructure to provide related R&D departments with an environment to innovate and improve autonomous driving technology in order to boost its competitiveness. The autonomous navigation of heavy-duty trucks is not only a leading innovation that will transform the trade logistics industry, but also is expected to reduce the number of large road accidents that occur on busy roads each year due to human error.

“This successful demonstration proves that innovative autonomous driving technology can be used to transform the trade logistics industry,” said Maik Ziegler, Ph.D., director of the Commercial Vehicle R&D Strategy Group at Hyundai Motor Co. “At this stage, a human driver is still used to control the vehicle manually in certain situations, but I think we will achieve Level 4 automation soon as we are constantly upgrading our technological capability.”

The demonstration, which took place on Aug. 21, was conducted using Hyundai’s Xcient model truck, which has a maximum load capacity of 40 tons. This was semi-equipped with a Society of Automotive Engineers (SAE) standard Level 3 autonomous driving system, enabling it to steer, accelerate or decelerate, and maneuver through traffic, all without human input. A human driver was on-board to take over manual control when required.

The vehicle was equipped with innovative technology features, which enabled it to maintain and change lanes during the natural flow of traffic, detect lane changes made by vehicles in front of it, navigate through tunnels and perform a complete halt or accelerate according to road traffic.

For the demonstration the Ministry of Land, Infrastructure and Transport (MOLIT) issued a temporary autonomous driving license for the first time to a heavy-duty truck. Hyundai Motor, in cooperation with its trade subsidiary Hyundai Glovis, utilized this opportunity to test the application of autonomous driving for use in the trade logistics industry.

The Test Route

The test route the most frequently travelled section for vehicles heading to the Port of Incheon for Hyundai Glovis’s parts transportation. This includes 40km in total of automobile highway. The truck successfully completed the journey, travelling 40km (24.8 miles) in 1 hour, while abiding strictly to the expressway speed limit of 90km/h (about 56 mph).

Hyundai Motor says it is planning to undertake further autonomous navigation technology tests in future in a variety of areas like Busan, and plans to concentrate on its enterprise development capabilities with the aim of early commercialization of the technology.

Autonomous Truck Technology

Expressways headed toward the Port of Incheon display heavy traffic even during weekdays, due to a high quantity of goods being exported. Therefore the vehicle’s autonomous technology and know-how had to be sufficient enough to adapt to unprecedented situations throughout the journey.

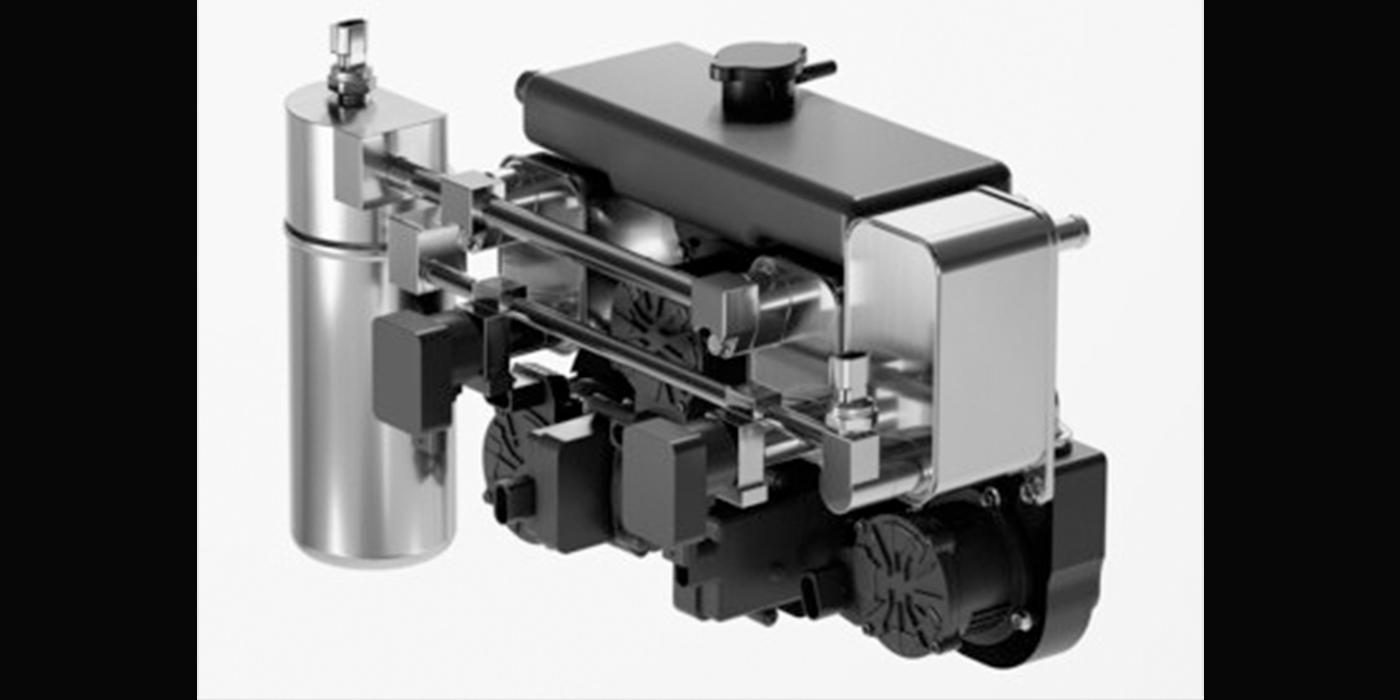

In addition, the semi-trailer truck is approximately 3.5 times longer, 1.4 times wider and 9.2 times heavier than the average compact sedan, when comparing to an empty truck’s weight. This requires an advanced and detailed autonomous navigation system. Accordingly, Hyundai Motor equipped sensors similar to the ones featured in autonomous sedans, and additional sensors optimized for heavy-duty trucks, like a hitch angle sensor and trailer rear radar sensor.

Ten different sensors, including three front and side-rear cameras, two frontal and rear radars, and three LiDARs in the front and sides allow the truck to be safely stabilized upon sharp turns. There also is a hitch angle sensor in the trailer coupler which computes the change in angle between the truck and trailer in real-time.

The data collected by each sensor collaborates with the HD map and sends information to the electronic control module for localization. The module makes accurate decisions for each situation, controlling the speed, steering and breaking accordingly.

A new steering control system (MAHS: Motor Assist Hydraulic Steering) developed by Hyundai Mobis also was implemented, providing a precise steering mechanism that controls the steering angle depending on the decision made by the electronic control unit. This minimizes the effort required to steer the vehicle, reducing driver fatigue.

Trade Logistics Industry Innovation

The introduction of the autonomous truck to trade logistics is predicted to instigate groundbreaking change in the industry, which is ridding itself of its traditional industrial image by integrating innovative technology like autonomous navigation, IoT and mobility technology to reform as a state-of-the-art technology industry.

Autonomous trucks maximize efficiency by maintaining the most efficient speed and velocity, reducing fuel costs, which make up one-third of long distance delivery costs, and thereby lowering the vehicles carbon footprint.

“Hyundai Glovis’ success in utilizing self-driving trucks as part of its delivery service proves that the self-driving technology is being utilized in actual logistics transport and can lead to mutual development,” said Sang-Sok Suh, Ph.D., head of strategy and planning group at Hyundai Glovis. “The company will be a leader in adopting future mobility technology like autonomous driving for the trade logistics industry.”

In the distribution industry, when multiple trucks travel in a convoy all vehicles precisely follow the path of the leading vehicle. Hyundai is currently investing in truck platooning technology that will enable this process to continue with autonomous vehicles, which it plans to complete by 2020.

Safety

According to the Korean National Police Agency traffic accident statistics, trucks are involved in 10.8 percent of accidents each year, which is second to private vehicles at 53 percent. Also, the potential threat of a severe accident is relatively higher when a truck is involved in a collision, with a fatality rate of 3.7 percent versus 1.9 percent non-truck involved accidents.

The number of casualties from truck accidents is increasing every year. Truck drivers often travel long-distance overnight, which can cause sleep deprivation resulting in dangerous driving. Autonomous technology implemented into commercial trucks is expected to reduce this.

Hyundai Motor is actively working to prevent accidents and minimize related damage by implementing next-generation driver assistant systems into large-sized trucks and buses currently being sold in the market.

The company offers options such as forward collision-avoidance assist (FCA), smart cruise control (SCC) and lane departure warning (LDW) in its Xcient model, and applied FCA and LDW as default options in all models of Hyundai Universe.

Hyundai Motor previously succeeded in Level 4 autonomous driving with Ioniq vehicles in downtown Las Vegas last year, and completed a 190 km (118 mile) journey from Seoul to Pyeongchang with Level 4 autonomously driven hydrogen electric NEXO and Genesis G80 vehicles during the Pyeongchang 2018 Olympic Winter Games.