Greenville (SC) Technical College (GTC) and KUKA USA have formed a unique partnership that will allow KUKA to train employees of its global customers at GTC’s Center for Manufacturing Innovation (CMI) and give GTC students access to the same resources.

Greenville (SC) Technical College (GTC) and KUKA USA have formed a unique partnership that will allow KUKA to train employees of its global customers at GTC’s Center for Manufacturing Innovation (CMI) and give GTC students access to the same resources.

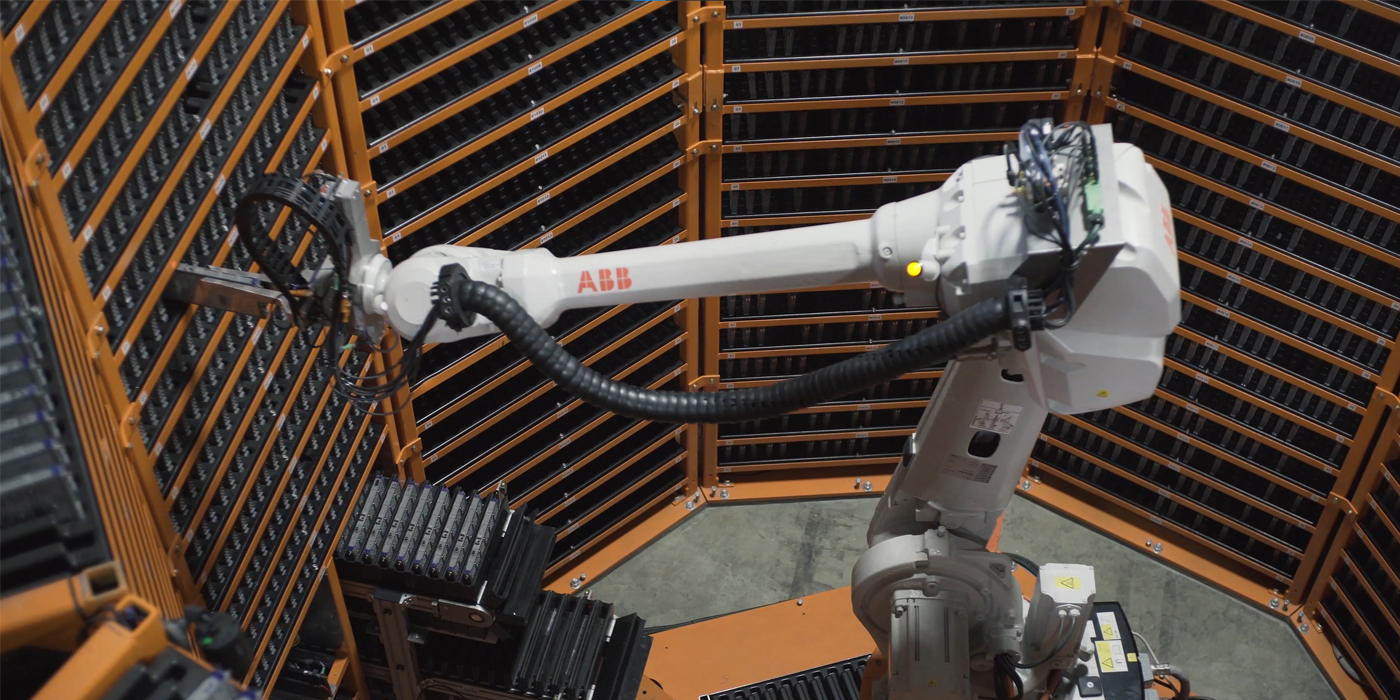

KUKA is a global automation corporation with sales of around 3.5 billion euro and around 14,200 employees. As leading global supplier of intelligent automation solutions, KUKA offers its customers in the automotive, electronics, consumer goods, metalworking, logistics/e-commerce, healthcare and service robotics industries everything they need from a single source: from components and cells to fully automated systems.

The partnership helps the Center for Manufacturing Innovation work to advance the level of technical training offered to students seeking associate degrees in advanced manufacturing technologies. Students will soon have the opportunity to earn an industry-recognized KUKA certificate as part of their studies.

The GTC Center for Manufacturing Innovation is one of three facilities in the U.S. that has access to this level of robotics training, the second being KUKA’s North American headquarters in Michigan and the third at KUKA’s west coast location in Fremont, California.

“We are excited to work with KUKA,” said David Clayton, executive director at the Center for Manufacturing Innovation. “KUKA is an industry leader in robotics and automation, and this partnership will build on our vision for CMI as the hub for advanced manufacturing in the southeast. The partnership gives our students access to the latest technology and curricula, allowing them to earn a certificate that will set them apart in their careers.”

Four large robot cells have been installed at CMI, and a dedicated KUKA trainer began offering classes in early September. This equipment adds to CMI’s diverse set of manufacturing technologies including 5-axis machining centers, fully automated manufacturing assembly systems, and additive manufacturing technology. Thousands of KUKA robots have been installed in the region supporting advanced manufacturers.

“As manufacturing industries, such as automotive and aerospace, continue to grow in the southeast, technical and robotics training will only become more prevalent,” said Joe Gemma, chief regional officer at KUKA USA. “We’re excited to partner with Greenville Technical College to help students and businesses alike improve their knowledge with our advanced robots and in-depth training.”

Earlier this year, the Vehicle Assembly Center opened at CMI in cooperation with Clemson University, BMW, and other partners to test new manufacturing processes and technologies away from the factory floor. Students experience scenarios related to safety, facility planning, and integrated systems without interrupting production as they complete research and development projects. This center also bridges the gap between the education of the engineer and technician, as students from Greenville Technical College and Clemson work together in teams to meet the demands of industrial clients.

Since the Center for Manufacturing Innovation opened nearly two years ago, it has helped to create awareness of opportunities in manufacturing with nearly 7,000 visitors including students from dozens of schools coming through the doors. Since 2016, enrollment in programs offered at CMI has grown rapidly, with nearly 500 students enrolled in mechatronics and machine tool technology programs and more than 800 pursuing manufacturing-related education.

To learn more about GTC, KUKA, and their partnership to improve training resources in the southeast, visit gvltec.edu.